🔧Applied by spray or brush, our innovative galvanic coating GALVAGRID® uses a unique anodic protection technology, suitable for both new and ageing steel structures.

🔁 It gives a second life to weathered galvanised assets – or can even double their service life in the most demanding environments.

🌊Rated up to C5-H, it is ideally suited for coastal, saline, or highly corrosive zones.

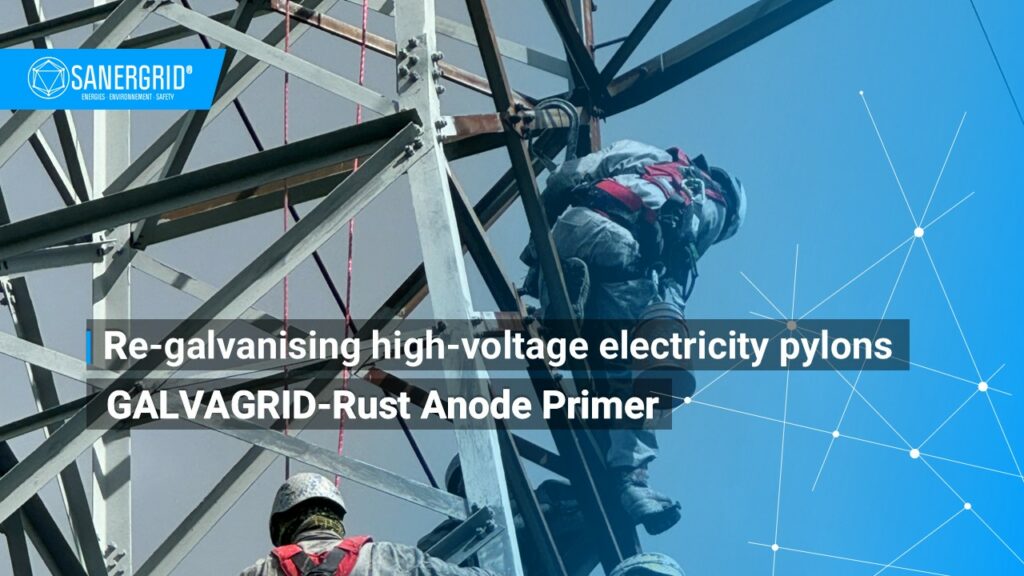

In the project pictured, our client observed premature corrosion on a recently hot-dip galvanised structure due to unexpected on-site conditions. Thanks to GALVAGRID® RUST-ANODE PRIMER PYLONE™, the steelwork was re-galvanised in place, achieving :

⏳ A minimum service life of 50 years

⚖️Uniform zinc thickness across all surfaces

🔗Seamless fusion with existing zinc layers

🔩Protection against bimetallic corrosion at bolted joints

✅ Already proven across Europe and North America, GALVAGRID® technology is a true game changer for maintaining steel structures in high-voltage substations and switchyards.

📩 Get in touch to learn more or assess your re-galvanisation project.

Visit our linkedin