T4T Retention tank for transformer transport

0,00 €

Galvanised steel containment for electrical transformers

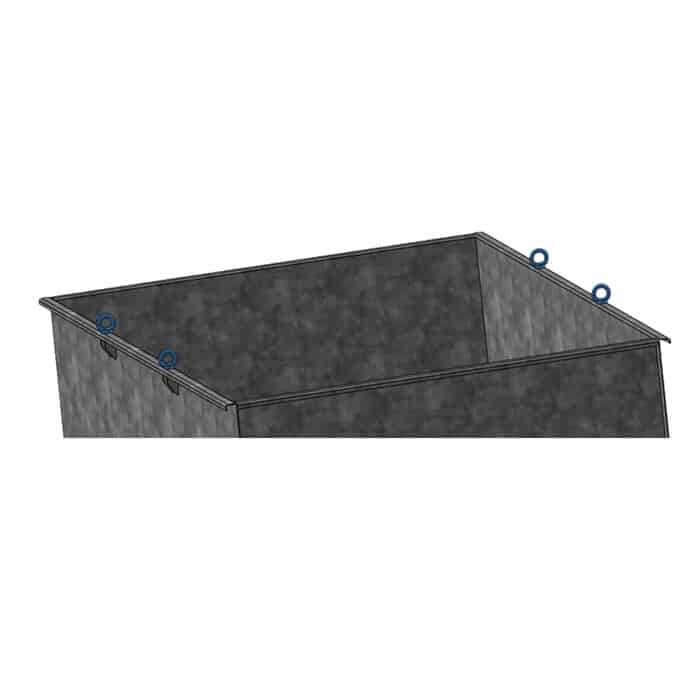

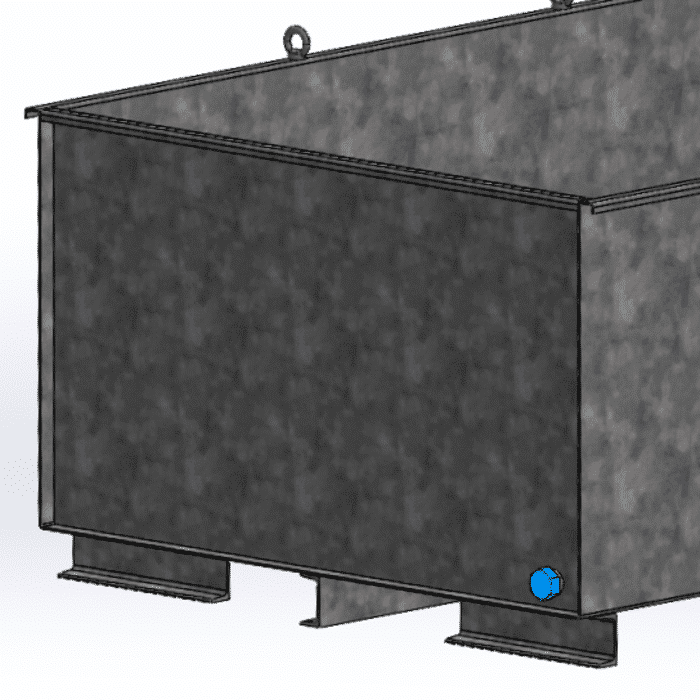

The T4T range comprises a number of standardised hot-dip galvanised steel retention tanks fitted with various attachment points to secure the transformer to the tank and the tank to the lorry during transport. T4Ts from SANERGRID® meet all the normative, technical and environmental requirements for oil-filled electrical transformers, in line with ADR requirements.

Description

Description

If an immersed transformer that uses oil for internal cooling or insulation needs to be transported by lorry, it needs to be protected against potential oil spills that could pollute the ground or water if they were to spread.

Moving the transformer can be difficult because of its weight and imposing dimensions. To overcome these difficulties, it is important to provide a suitable attachment system. Transport must also comply with the ADR standard for the transport of dangerous goods (TMD).

The T4T® range enables you to meet all the technical and regulatory requirements for transporting oil-filled electrical transformers, with or without PCBs, in accordance with the ADR standard.

The standard version of the T4T® range comprises a series of hot-dip galvanised steel retention tanks fitted with various attachment points for attaching the transformer to the tank and the tank to the truck. In each bund, a set of 2 longitudinal welded beams makes it easy to place the equipment support on top.

Accessories and options

The transformer containment has several options, such as hydrocarbon absorbents, a tarpaulin cover to prevent water from filling in, galvanised gratings for raising, a drain spigot, etc. to comply with ADR regulations on the transport of electrical transformers with or without PCBs.

Depending on the configuration of your project, the T4T range is available in 3 standard models: T4T800, T4T2000, T4T2500 or can be specially designed on request.

Technical data

Additional information

| Material | steel |

|---|---|

| Conditions of use | outside |

| Type of bin | Of transport |

| Fronts | Welded |

| Fire resistance | YES |

Use and maintenance

The T4T® retention tank ensures total containment of the dielectric at every stage of the transformer’s journey. With a height of 800 mm or more, the T4T® retention tank can be handled with a forklift truck and includes lifting rings for handling the tank.

Please refer to the user manual for further details. Failure to comply with good operating practice and failure to deal with anomalies and defects in the field are the responsibility of the owner of the equipment.

Additional information

Our transformers containment complies with EU Regulation No 548/2014 also known as ECODESIGN on the implementation of Directive 2009/125/EC, which lays down eco-design requirements for the placing on the market or putting into service of transformers with a power rating of at least 1 kVA used in 50 Hz electricity transmission and distribution networks or for industrial applications. Called ECODESIGN Tiers 1 (2015) and ECODESIGN Tiers 2 (2021).

Our standard range of SANERGRID T4T transport retention tanks comply with French, European and international standards and recommendations concerning the retention of dielectric fluids, fire risk management, the management of contaminants and rainwaters in high-voltage substations and the protection of people and property.

- French standards NF C13-100 and NF C13-200, which prevent the electrical risks of overcurrent, earthing problems, fire risks, short-circuits and lightning, soil pollution and environmental pollution.

- Standard NF EN 61936-1, relating to the design and installation of electrical installations, which requires watertight retention representing 100% of the volume of oil used, and provides the necessary indications for pre-dimensioning retention volumes and surfaces, fire safety distances and systems, and rainwater management associated with the outdoor storage of hydrocarbons.

- CIGRE 23-07 and IEEE 980 recommendations on the use of fire suffocating covers for transformer pits and tanks, as well as guidance on the pre-sizing of indoor and outdoor retention pits and tanks.

- Our retention tanks are designed and manufactured in accordance with the European norms and standards of EUROCODE 3 (Calculation of steel structures).

- Our manufacturing plants are certified ISO 9001 for their quality management process and IS0 14001 for their environmental management process and are all based in Europe to encourage short supply chains and limit carbon emissions.

- Our French and European sites enable us to guarantee that all our steel comes from European production, which is made up of over 50% recycled steel to limit the over-exploitation of resources and limit the carbon emissions linked to our manufacturing activities SANERGRID.