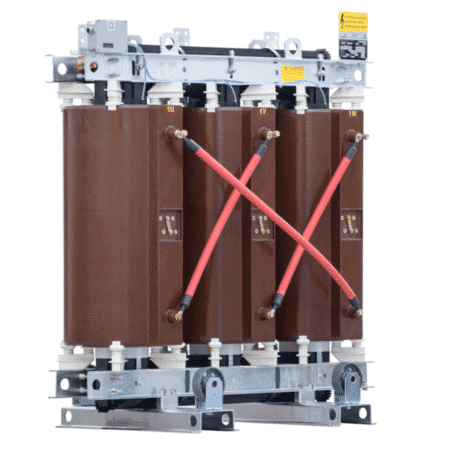

ECOTRAFO-SP Dry-type transformers for special HV/LV distribution

0,00 €

Trafo ELETTRO electrical transformer, casted resin dry-type, for special applications up to 54 kV

ECOTRAFO-SP™ standard range of TRAFOELETTRO HV/LV casted resin dry-type electrical transformers for electrical distribution up to 25 MVA, 20/0.4 kV, in 24kV insulation class with special UCC designs. High performance and efficiency even in difficult conditions, to provide a high level of safety and reliability for indoor use in demanding conditions such as hospitals, data centres, airports and any establishment receiving the public. Trafo ELETTRO know-how since 1969, our HV/LV dry-type transformers offer partial discharges < 5 pC, below the required 10 pC normative requirements, to guarantee an optimised lifetime of the dry-type transformer.

Description

Description

The TrafoELETTRO® special electrical distribution range for the French market called ECOTRAFO-SP™ consists of around twenty standardised and normalised references up to 25 MVA for special electrical distribution applications in buildings.

The advantages of Trafo ELETTRO® ‘s coated dry-type electrical transformers from the ECOTRAFO-SP™ range are mainly linked to the quality of the materials used and the factory know-how of our teams. Our TrafoELETTRO coated dry-type transformers are reputed to be among the most reliable on the market with an extremely low MTBF (Mean Time Between Failures).

To sum up, the ECOTRAFO-SP™ range of 20/0.41 kV encapsulated dry-type transformers is designed and manufactured along 3 axes of technical excellence for an optimum compromise between price and the proven technical design of the power distribution market.

TrafoELETTRO’s ECOTRAFO-SP™ HV/LV dry-type transformers are certified and compliant with the following classes:

- Environmental class E3:

Can be used in environments subject to heavy condensation (95% humidity) and heavy pollution. French national standard. On request, we can produce a class E4 “extremely polluted area”.

- Climatic class C2:

Suitable for operation, transport, and storage down to -25°C, ensuring the same level of performance even at low temperatures. French national standard. On request, we can produce C3 (Transport and storage at -40°C and operation at -50°C), C4 (The transformer is suitable for transport and storage at -50°C and operation at -40°C) or C5 (Transport and storage at -60°C and operation at -50°C).

- Fire behaviour class F1:

Self-extinguishing and low smoke emission in the event of fire, reduced risk of fire thanks to our resin’s low self-ignition properties.

Improved shock resistance:

Our transformers are designed, tested, and manufactured with a reinforced insulation class (improved shock resistance, BIL LIST 2), thanks to optimised insulation in sensitive areas of the device. We can quote for BIL1 on request.

Extended transformer life:

Thanks to the quality of the resin and the moulding and impregnation process, our transformers have a level of partial discharge on leaving the factory that exceeds the normative requirements of 10 Pc, with a measured level of less than 5 Pc.

Finally, the TrafoElettro® ECOTRAFO-SP™ Range of special dry-type transformers is produced at standardised power ratings, so you benefit from the actual power mentioned without any power derating. In addition, the weight of our equipment is a good indicator of respected power and respected design and insulation safety coefficients.

This is why our TrafoELETTRO ECOTRAFO-SP™ electric transformers come with a 2-year warranty subject to the TrafoELETTRO special sales conditions.

Complementary description of the standard TrafoELETTRO ECOTRAFO-SP™ range:

- Power ratings up to 25MVA, for standard normalised power ratings from 160 up to 3150 KVA see our ECODIS20™

- Special UCCs. For short circuit voltages: 6%, see our ECODIS20™ range.

- Frequency: 50 Hz, DYN11 coupling

- Rated insulation voltage: 24 kV. For insulation voltages of 15 or 36 kV consult our ECODIS15™ and ECODIS36™ For 15/20kV dual voltage transformers, consult our ECODIS-BI1520™ range.

- Rated impulse withstand voltage: 125 kV BIL2, for BIL1 at 95kV consult us.

- Protective enclosures: if you don’t want to stick with IP00, we design and manufacture our own IP or protective enclosures. We offer IP31 to IP43 For custom enclosures, IP54 or adaptations of busbars or plug-in terminals on IP roofs, please refer to the IP-TRSEC-SP range.

- Included by default: 4 lifting rings, 4 swivel rollers, HV side +/- 2×2.5 off-load tension adjustment bars; routine tests.

- Standard connection: MV on deck from above or below, LV on deck from above.

- Load changer

Contact us with details of your site and project requirements.

Accessories and options

- 3 PT100 temperature sensors, or 6 PTC For infrared temperature sensors, please contact us.

- Standard default T119, T154 relay: temperature control relay that triggers alarms and signals. Consult us to add digital or IoT (Internet of Things) functionality, ECOTRAFO-SP™ transformers are available with scalable digital functionality, which allows customers and users to add surveillance, monitoring, or data feedback for other digital tools to improve safety, reliability, and productivity.

- Plug-in terminals on the HV side of the ELASTIMOLD-HT coated dry-type transformer.

- Plug-in terminals on the HV side brought back to the roof or the IP side of the coated dry-type transformer: ELASTIMOLD-IP

- Guillotine-type locking device for HV terminals ready to receive a lock for the TGBT key: VERHTA

- Lock for IP31 or sash, AREL type or equivalent: VERSER

- Fans for forced cooling to increase power by up to 40% VENTI800, VENTI1600 and VENTI3150 range

- Electrostatic shield between MV and LV windings

- SANERVIB anti-vibration dampers to reduce transformer vibrations and the resulting noise.

Technical data

Additional information

| Conditions of use | indoor |

|---|---|

| Scope of application | Power ratings up to 25 MVA, Special UCC |

Use and maintenance

Refer to the user manual.

Maintenance:

Periodic maintenance of the transformer will maintain high efficiency over time and extend its service life.

- Cleaning dust, dirt deposits and foreign bodies from windings and cores

- Checking the tightening torques of components and medium and low voltage connections, including earthing.

- Checking the operation of the thermometric control unit and probes

- Cleaning of windings and medium- and low-voltage terminals, including cooling channels

Failure to comply with good practice in use and failure to deal with anomalies and defects in the field are the responsibility of the owner of the equipment.

Additional information

Trafo ELETTRO coated dry-type transformers in the ECOTRAFO-SP™ Range meet international industry standards, including IEC, EN or ANSI.

REFERENCE STANDARDS:

All our transformers are manufactured in accordance with the following standards:

- IEC 60076-11-CEI 14-8 – Dry-type power transformers

- IEC 60076-1-CEI EN 60076-1 – Power transformers – Part 1: General.

- IEC 60076-2-CEI EN 60076-2 – Power transformers – Part 2: Heating.

- IEC 60076-3-CEI EN 60076-3 – Power transformers – Part 3: Insulation levels, dielectric tests, and clearance distances in air.

- IEC 60076-5-CEI EN 60076-5 – Power transformers – Part 5: Short-circuit withstand capability.

- IEC 60076-10-CEI EN 60076-10 – Power transformers – Part 10: Determination of noise levels.

- IEC 60270-CEI EN 60270 – High voltage test technique. Measurement of partial discharges.

- IEC 61378-1-CEI EN 61378-1 – Conversion Transformers – Part 1: Transformers for Industrial Applications.

- HD 538.1 S1-CEI 14-12 – Three-phase dry-type distribution transformers – Part 1: General requirements and requirements for transformers with a highest voltage for equipment not exceeding 24 kV.

Compliance with these standards is guaranteed by UNI EN ISO 9001:2008, the company’s quality management standard.

Routine tests included in the offer (in accordance with Standards EN60076-11):

- Measurement of transformation ratio and polarity.

- Applied voltage withstand test.

- Induced voltage withstand test.

- Measurement of partial discharges.

- Measurement of losses and no-load current

- Measurement of short-circuit voltage and short-circuit losses.

- Measurement of winding resistance.

- Check dimensions, presence, and operation of accessories.

Type tests not included in the offer on request:

- Impulse test in accordance with standard IEC EN 60076-3

- Temperature rise test in accordance with standard IEC EN 60076-2

- Noise level measurement in accordance with standard IEC EN 60076-10

- Dynamic short-circuits resistance test in accordance with standard IEC EN 60076

All TrafoELETTRO® equipment is produced in Italy, and the raw materials used are mainly European in origin, to limit transport emissions, and as far as possible from recycled products.

All our TrafoELETTRO® transformers in the ECOTRAFO-SP™ range are designed according to an eco-design approach applicable from 1 July 2021 (European regulation 548/2014/EU) with a maximum no-load loss of -10% of A0 (standard 50708-2-1) to limit the use of raw materials.

European Directive 2009/125/EC establishes a framework for setting ecodesign requirements for energy-related products. It is part of the European objectives to reduce energy consumption and cut CO2 emissions. European Commission Regulation No 548/2014 of 21 May 2014 defines the application of the directive for transformers. It applies to appliances ordered from 1 July 2015. It defines 2 energy performance tiers: Tier 1 applicable from 1 July 2015 and Tier 2 applicable from 1 July 2021.

Standard EN 50629 defines the rules for applying and checking this directive for high-power transformers (Um > 36 kV or Sr ≥ 40 MVA). These regulations apply to all new transformers installed in the European Community.

The transformer manufacturer is responsible for complying with the law and designing a transformer that meets the energy efficiency criteria defined by the European Commission regulation. The application of the regulation does not provide for any tolerance in terms of meeting the PEI criterion. If the minimum requirement is exceeded, the transformer will be banned from the market.

Requirements for product information: Compliance with the regulation and the CE mark requires that the product documentation and the nameplate on the appliance show at least the following information:

- Nominal apparent power,

- Value of the energy efficiency index (PEI) and the power (SPEI) at which it is achieved,

- Load and no-load losses,

- Consumption of the cooling system to remove calories at SPEI,

- Indication of the mass and nature of the transformer’s main components (copper, magnetic sheet, etc.)

Note: In the case of double-voltage transformers on the low-voltage side, losses are calculated based on the highest low-voltage of the low-voltage winding.