E/FOURREAU Insulating bird protection sheath for live cables

0,00 €

Midsun® insulating sheaths, self-closing, made of silicone, bird protection for HV cables and pipes

The Midsun E/FOURREAU range is made up of numerous references of silicone rubber sheaths that provide high quality insulation for overhead distribution lines, cables and substation busbars ; up to 35 kV between phase and earth.

Description

Description

The E/FOURREAU sheath is a silicone layer that can be installed on the cables and busbars of your electrical distribution installations and substations to provide insulation of up to 35 kV from phase to earth, thereby helping to protect birdlife. Its highly resistant material is suitable for harsh outdoor conditions in electrical substations.

The E/FOURREAU is manufactured with a slot to allow easy application without having to cut the electrical connections (see Use and Maintenance tab). The sheath is simply opened and stretched, allowing it to slide quickly over the cable or busbar to be protected. No thermal shrinkage is required for its application. No tools other than a cutting tool are required to obtain the appropriate length.

Description of the Midsun® E/FOURREAU AVIFAUNE range :

- Silicone rubber compound

- Standard colour grey, other colours available on request

- External conductor diameter: from 6.35 to 11.35 mm

- Packaging: minimum 15.2 m

- Insulation level: 35 kV phase to earth

- High resistance to UV, arcs, ozone and dielectrics

- High thermal endurance over a long period

- Increased creepage distance

- Durometer: 65 +/- 10 shore A

- Tensile strength: 600%.

- Breaking point: 90

- Self-extinguishing: in 15 s

Products in the E/FOURREAU range have a shelf life of 5 years from the date of manufacture; they should be stored between 10°C and 27°C and at a relative humidity of <75%.

Applied in accordance with the recommendations of the manufacturer MIDSUN® and under the supervision of a SANERGRID® technical expert , this product is guaranteed by the manufacturer for a minimum of 10 years.

We have 11 references to cover your needs. Contact us with details of your site and project requirements.

Accessories and options

The Avifaune range is available in several references:

- Cut-to-size insulation panels: E/PLAQUE range

- Self-fusing insulation tapes: E/TAPE range

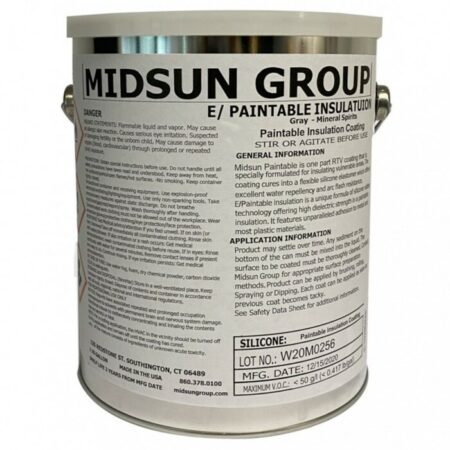

- Silicone insulating paint: E/PEINTISO range

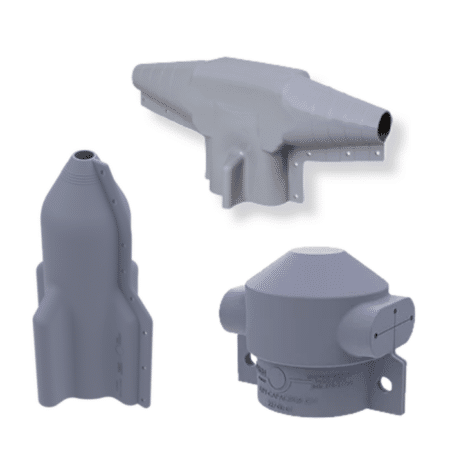

- Standard and made-to-measure pre-formed protective covers: E/COVER range

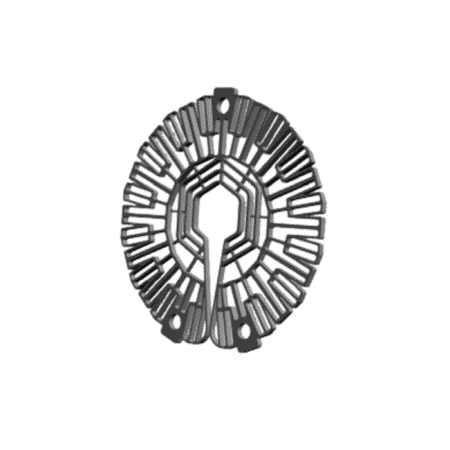

- Disc-shaped barriers: E/BARRIER range

Other Midsun® solutions :

- Self-cleaning hydrophobic silicone paint: HVIC range

- Anti-corrosion paint: SILPROCOAT range

Technical data

Additional information

| Conditions of use | outside |

|---|---|

| Material | Silicon |

Use and maintenance

Before installation:

Make sure that the Avifaune product and the device are clean. Remove dust, dirt and moisture from your hands, otherwise the sheath may not stick properly.

Installation:

- Open the sheath and wrap it around the conductor.

- For horizontal busbar applications, roll the slotted side down to limit rainwater penetration.

- Once installed, make sure that the E/FOURREAU sheath is completely closed around the conductor.

Refer to the user manual for further details.

The owner of the equipment is responsible for and liable for any failure to comply with good operating practice and for any failure to deal with anomalies and defects in the field.

Additional information

Tests carried out in accordance with current international standards:

- ASTM D2303: Resistance to partial discharge and erosion (1h at 3.5 kV)

- ASTM G154: UV stability (100% at 75,000h)

- ASTM D638: Thermal endurance (105°C continuous)

- ASTM D638: Ultimate elongation (400%)

- ASTM D149: Dielectric strength (400V/mm)

- ASTM D412: Elongation at break and tensile strength (300% and 600%)

- ASTM D2240: Durometer (65 +/- 10 shore A)

- ASTM D74C: Breaking point F 90

- ANSI C37.20: Flammability, in accordance with standard

- ISO /R 62: Water absorption (1% max after 14 days at 23°C)

- ASTM D2671, procedure C: Flexibility at low temperature (no cracking after 4h)

- ASTM 2671, procedure B: Corrosion (visual inspection passed after 16h)

Videos

You may also like…

-

E/COVER Removable insulating covers for bird protection

0,00 € -

E/PLAQUE Silicone cover for bird protection

0,00 € -

HVIC Cleaning coating for high voltage insulators

0,00 € -

E/BARRIER Thermoplastic disc for bird protection

0,00 € -

E/PEINTISO Silicone insulating paint for bird protection

0,00 € -

E/TAPE Self-fusing silicone tape for bird protection

0,00 €