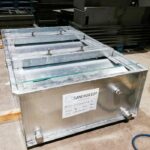

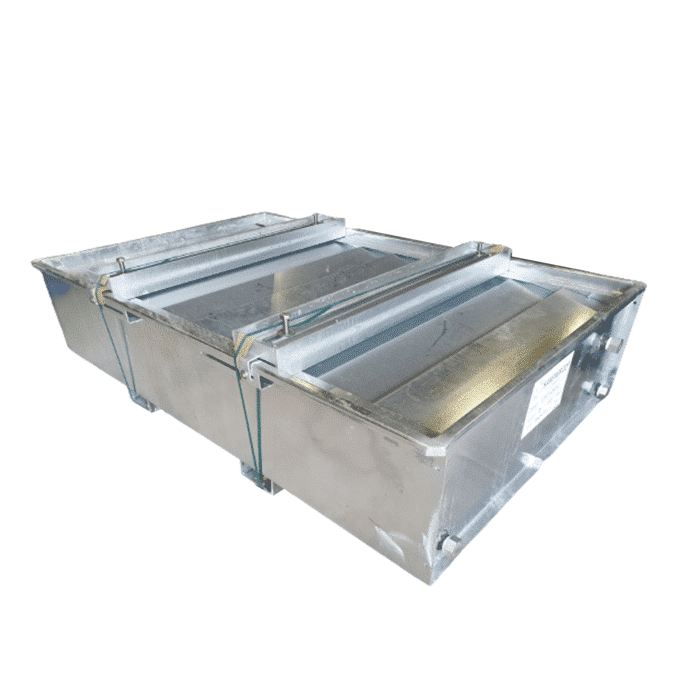

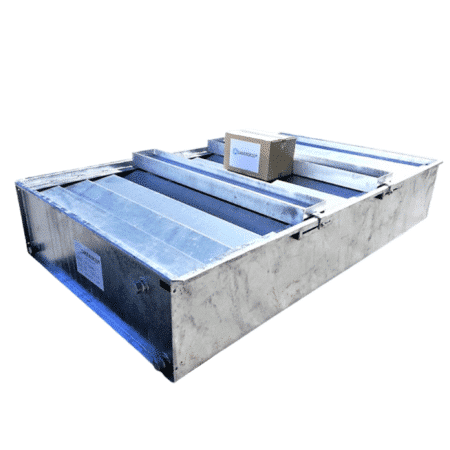

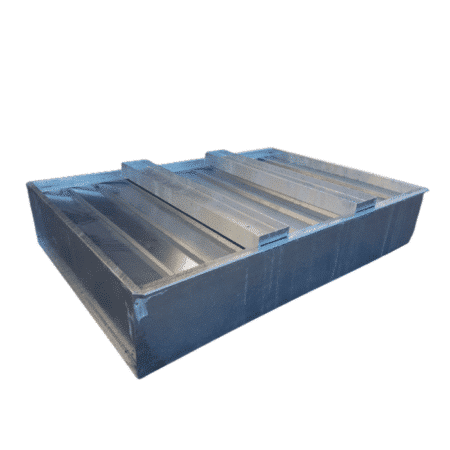

ERT®-R Extinguishing retention tank with roll-on adaptation for transformers

0,00 €

Tank with suffocating slats for electrical transformers

The ERT® R range comprises a number of standardised, self-supporting, one-piece fireproof enclosures with width-adjustable beams, which can be adapted so that the transformer can be rolled onto the enclosure. SANERGRID®‘s ERT-R range meets all the regulatory, technical and environmental requirements for dielectric oil transformers.

Description

Description

The range of ERT-R containers includes adaptations to enable the transformer and ERT container package to be rolled using the transformer’s own wheels. Our engineering department defines the structure for adapting the transformer wheels to the standard transformer containment unit for ranges from 160 to 3150 kVA, and customised units for higher power ratings or special configurations (IC, TSA, TCI, AT, etc.). The ERT-R option does not include wheels.

Description of the standard ERT-R range:

- S235 steel tank, thickness 3, 4 or 5 mm; hot-dip galvanising certificate to ISO EN1461-2022.

- Double watertight welding on all parts of the retention tank area to ensure complete watertightness, with individual quality inspection before leaving the factory.

- The upper part of each tank is fitted with an EXTICOV CCF type extinguishing system consisting of CNPP-tested suffocating slats.

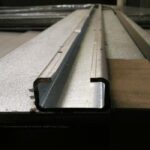

- A set of 2 support beams is fitted widthways above each ERT-R tray, making it easy to place the equipment on the trays. The support beams are adjustable: their ideal position corresponds to the ECODESIGN standard; they can however be moved forward or backwards by one notch in relation to this standard. They are fastened to oblong-hole plates using 4 HM10x30 bolts with stainless steel “nylstop” locknuts and wide washers (LL) (supplied).

- The maximum weight of the transformer on the ERT® R enclosure is calculated according to the NFC 51.51 standard centre-to-centre distance.

- At the foot of the bund, two watertight wall penetrations are available to accept 1.5″ ¼-turn valves: the first valve to allow the bund to be emptied, and the second to fit an SPI® PETRO PIT rainwaters filtration kit. In the standard version, the bund is supplied with the two wall passages closed watertight with stainless steel plugs.

- ERT-R drip trays are always fitted with a safety siphon, which is fitted at the bottom of the drip tray. In the event of heavy rain or a blockage in the filtration system, the safety siphon allows overflowing water to be drained away without draining oil.

ERT® R tank guarantee a service life in indoor and outdoor conditions similar to that of the electrical transformer or other machine they are fitted with.

Accessories and options

The ERT® range comprises a range of one-piece retention tanks with different retention volumes, depending on whether you use the tank indoors or outdoors. Please contact us with your transformer dimensions.

Depending on the configuration of your project, the ERT® range is available in several versions:

- Width-adjustable beams: ERT-W range

- Fixed beams where the transformer centre distance is known: ERT-F-W range (widthways) and ERT-F-L range (lengthways)

- Length-adjustable beams when the entrance to the substation is through the door or when the site configuration requires it: ERT-L range

- Addition of a grating to walk on the containment and access the transformer control unit, DGPT2 or auxiliary cabinets: ERT-AUX range

- Reinforced sizing for ENEDIS autotransformers, compensation impedances, Peterson coils, etc. ERT-AT range (adjustable beams) and ERT-F-AT range (fixed beams)

- Non-bearing extinguishing retention tank when embedded in a retention pit, under an MV substation or photovoltaic skid: ERT-NP range

- Rolling trough with fixed beams, when the centre-to-centre distance of the transformer is known, to roll the trough directly with the transformer fixed on top, reusing the latter’s wheels: ERT-F-R range.

- Modular containers for larger transformers where the container width exceeds the European transport gauge, the containers are placed side by side and joined together in 2, 3, 4, 5 or “N” modules connected together using the SNG-Flow™ system: ERT MODULO range.

- For skid-mounted photovoltaic applications, to integrate the retention tank between the skid and the transformer: ERT-SKID range

- For any bespoke application where you need to roll the transformer onto the tray, roll the tray with the transformer, or a special geometry or design: consult our project managers: ERT-SP range

This range also includes a number of accessories to suit your needs:

- PETRO PIT kit, for use outdoors to allow continuous drainage of rainwater.

- Lifting hooks.

- SANERVIB anti-vibration pads.

- Galvanic anti-corrosion treatment C5H GALVAGRID®.

- Self-locking directional wheels: ROLL.

- Inspection hatch.

- Earthing, MALT.

- Wheel locking calipers, SANERBLOCK™.

- Railing and access staircase.

- Bracket for fixing and hanging on a photovoltaic skid or on the ground.

- Rolling options: SANER-Rail, SANER-Grantex and Rippage (range for fixed beams only).

Technical data

Additional information

| Material | steel |

|---|---|

| Conditions of use | indoor, outside |

| Type of bin | fireproof, self-supporting |

| Beams | Adjustable, Widthwise |

| Fire resistance | YES |

Use and maintenance

Before installing the tank:

- Make sure that the ground surface is smooth, flat, clean and, above all, large enough to take the weight of the transformer and the ERT® -R container.

- Check that the positioning of the load pick-ups from the floor to the tray is appropriate, aligned and correctly dimensioned.

- If the bins are stored outside, they must be emptied regularly, and not handled with water inside.

Installing the tank:

The tray must be unloaded using suitable handling equipment. Once installed in its final position, fix the support beams, adjusting the centre-to-centre distance so that the transformer is centred on the supports of the ERT® tank.

Installation by rolling or shifting :

In the event of handling by rolling the transformer onto the tank or shifting the transformer from the lorry onto the tank, please consult us beforehand or refer to the SANER-Rail, SANER-Grantex and Rippage options.

Maintenance:

Regular visual inspection of the equipment should cover the following points:

- Installation of suffocating slats: no overlaps or missing slats, presence of CCF-STOP™, maintenance slat lockout screw.

- Tightness at wall penetrations, accessories and/or plugs correctly screwed in.

- Integrity of the tank walls, no deformation or damage (knocks, impacts, rust, etc.).

- State of ageing of the hot-dip galvanising protective layer and potential touch-ups.

- Check that rainwater is flowing properly through the filters: if they are clogged, clean the pre-filters, or change the filters if they are saturated or have exceeded their recommended service life.

- The frequency of these checks depends on the constraints of each site, depending on its degree of corrosion, dirtiness, presence of organic matter, etc.

Refer to the user manual for further details.

The owner of the equipment is responsible for and liable for any failure to comply with good usage practices and for any failure to deal with anomalies and defects in the field.

Additional information

Our transformers are in line with EU Regulation No 548/2014 also known as ECODESIGN on the implementation of Directive 2009/125/EC, which lays down ecodesign requirements for the placing on the market or putting into service of transformers with a power rating of at least 1 kVA used in 50 Hz electricity transmission and distribution networks or for industrial applications. Called ECODESIGN Tiers 1 (2015) and ECODESIGN Tiers 2 (2021).

Our standard range of SANERGRID ERT-R retention tanks complies with French, European and international standards and recommendations concerning the retention of dielectric fluids, fire risk management, the management of contaminants and rainwaters in high-voltage substations and the protection of people and property.

- French standards NF C13-100 and NF C13-200 prevent electrical risks, overcurrents, earthing problems, fire risks, short circuits and lightning, soil pollution and environmental pollution.

- Standard NF EN 61936-1, relating to the design and installation of electrical installations, which requires watertight retention representing 100% of the volume of oil used, and provides the necessary indications for pre-dimensioning retention volumes and surfaces, fire safety distances and systems, and rainwater management associated with the outdoor storage of hydrocarbons.

- CIGRE 23-07 and IEEE 980 recommendations on the use of fire suffocating covers for transformer pits and tanks, as well as guidance on the pre-sizing of indoor and outdoor retention pits and tanks.

- Our retention tanks are designed and manufactured in accordance with the European norms and standards of EUROCODE 3 (Calculation of steel structures).

- Our manufacturing plants are certified ISO 9001 for their quality management process and IS0 14001 for their environmental management process, and are all based in Europe to encourage short supply chains and limit carbon emissions.

- Our French and European locations enable us to guarantee that all our steel comes from European production, which is made up of over 50% recycled steel in order to limit the over-exploitation of resources and limit the carbon emissions linked to our manufacturing activities SANERGRID.

- Rainwater drainage and oil pollution for outdoor use:

Thanks to the SPI anti hydrocarbons filter system, the tank is empty of water most of the time and ready to receive hydrocarbons. In compliance with the French Water Act (decree 77-254), the water discharged from the tanks is not contaminated with more than 5 ppm of hydrocarbons, in accordance with standard EN 858-1 (“light liquid separation installations”).

SPI® filters are regularly tested by independent laboratories: SANERGRID Bureau Veritas COFRAC D. certified report: 003606/2776443/1/1/1 in 2015 (France), SPI Phoenix I.D. laboratory reports: AR67044 from 2002, 2004, 2005, 2009, 2018, 2022 (USA), TÜV report Nr 2432974 in 2016 (Germany), NUA -Z-11895-1/1-2016 report. (Non-exhaustive list)

Videos

Our selection for you…

-

EXTICOV-CCF Cover with special single-slope fire suffocating slats

0,00 € -

ERT-MODULO Modular extinguishing retention tank

0,00 € -

PTFE Teflon plates for electrical insulation

0,00 € -

MALT Flexible earthing braids for electrical substations

0,00 € -

ERT-W Extinguishing retention tank with width-adjustable beams

0,00 € -

ERT-F-W Extinguishing retention tank with widthways fixed beams

0,00 € -

SANERBLOCK Locking brackets for transformer wheels

0,00 €