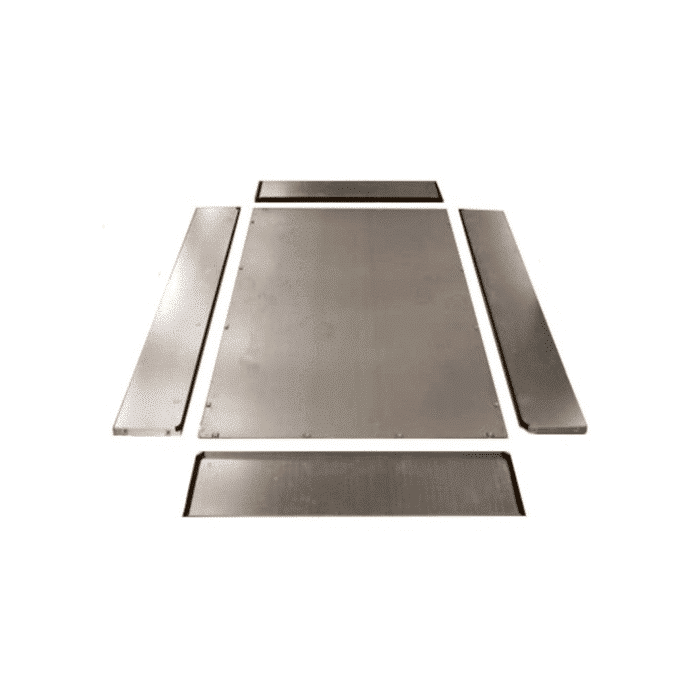

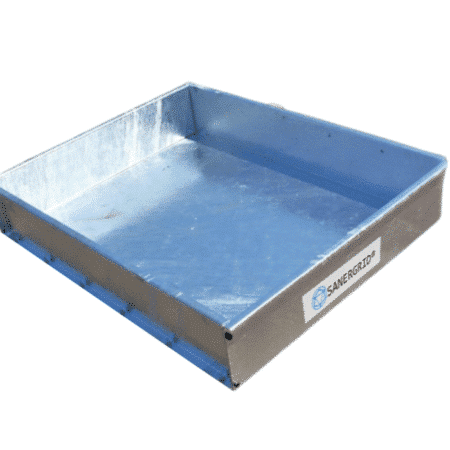

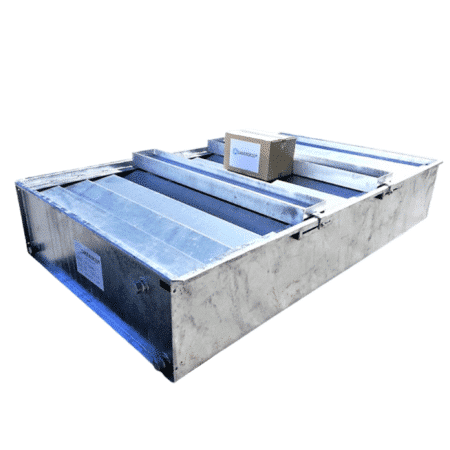

BDRSA Single retention tank with 4 removable walls

0,00 €

Tank for electrical transformers

The BDRSA range comprises several standardised references of removable monobloc tanks with 4 removable walls. SANERGRID®‘s BDRSA range meets all the regulatory, technical and environmental requirements for dielectric oil transformers from 160 to 2,500 kVA.

Description

Description

Description of the BDRSA standard range:

- S235 steel tank, sheet thickness from 20 to 30/10

- 4 removable walls to be bolted on using pan bolts on lock nuts (supplied)

- Technical seal in special SILGRID™ silicone with high temperature resistance and hot dielectric oil on all removable parts of the tank, to be applied after installation of the transformer in the tank and closure of the front panels to guarantee complete watertightness of the tank.

- Unit quality inspection before leaving the factory, with the bins arriving pre-assembled with their bolts and nuts pre-installed.

- Earthing output available at 2 opposite points (terminal not supplied)

- Watertight double-sided welding, welding process regularly tested by third-party inspection bodies using the ARDROX 996 P2 penetrant testing process or equivalent.

By default, our BDRSA containers are hot-dip galvanised to guarantee superior internal and external performance compared with C3 paint. They are certified hot-dip galvanised in accordance with ISO EN1461-2022.

The BDRSA range comprises a number of standardised retention tanks for ECODESIGN Tier 2 distribution transformers. They allow you to comply with the required retention volume, as well as the length and width of your transformers. Please contact us with your transformer dimensions.

Please note that since the AFNOR update in 2021 on the NFC13200, simple retention tanks not fitted with suffocating slats on the inside, regardless of their capacity, are no longer authorised. We recommend that you consult us if you have any problems with heightening or dimensions, and that you contact our inspection body, such as APAVE, SOCOTEC or Bureau Veritas (or other), to obtain the necessary exemptions from your insurance organisations.

Accessories and options

Depending on the configuration of your project, the BDRG range can evolve into several custom designs thanks to our in-house design office and dedicated manufacturing plants:

- Addition of rolling UPNs inside the tray in length or width: BDRG-ROLL range

- Tray design with 2 detachable fronts in length and/or width: BDRG-2 range

- Tray design with 1, 2, 3 or 4 detachable fronts in length and/or width: BDRG-SP range

Several options are also available for special applications

- SPI® anti-hydrocarbons filters, when the tray is used outdoors for continuous rainwater drainage. In this case, we recommend the TRT® range of all-welded fronts

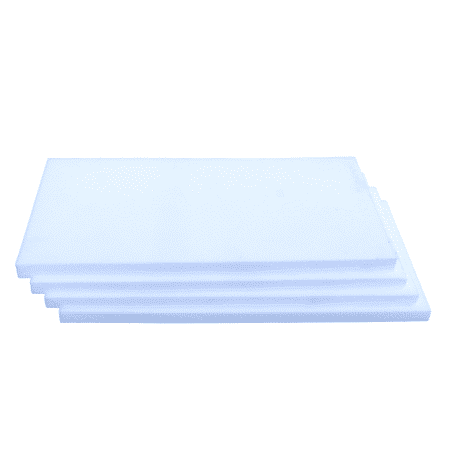

- SANERVIB anti-vibration pads for installation at the bottom of the tank to reduce transformer noise and vibration.

- Inner tracks in UPN BDRG-ROLL

- Change of surface treatment to paint class C3, C4 or C5

- Galvanic anti-corrosion treatment C5H or CX in GALVAGRID®

- Locking brackets for transformer wheels: SANERBLOCK™

- Bracket for fixing and anchoring to the ground.

Technical data

Additional information

| Material | steel |

|---|---|

| Conditions of use | indoor, outside |

| Fronts | Removable |

| Type of bin | self-supporting |

| Fire resistance | YES |

Use and maintenance

Before installing the tray:

- Make sure that the floor surface is smooth, flat, clean and, above all, large enough to take the weight of the transformer and the container.

- Check that the positioning of the load pick-ups from the floor to the tray is appropriate, aligned and correctly dimensioned.

- If the bins are stored outside, they must be emptied regularly, and not handled with water inside.

Installing the tray:

The bund must be unloaded using suitable handling equipment. Once in its final position, install the transformer in the retention tank, close the front panels with pan bolts and apply the SILGRID silicone sealant cartridge to ensure complete watertightness.

Maintenance:

Regular visual inspection of the equipment should cover the following points:

- Tightness on detachable fronts, wall penetrations and accessories and/or plugs properly screwed in if present

- Integrity of the tank walls, no deformation or damage (knocks, impacts, rust, etc.).

- State of ageing of the hot-dip galvanising protective layer and potential touch-ups.

- The frequency of these checks depends on the constraints of each site, depending on its degree of corrosion, dirtiness, presence of organic matter, etc.

Please refer to the user manual for further details. Failure to comply with good operating practice and failure to deal with anomalies and defects in the field are the responsibility of the owner of the equipment.

Additional information

Our transformers containment complies with EU Regulation No 548/2014 also known as ECODESIGN on the implementation of Directive 2009/125/EC, which lays down ecodesign requirements for the placing on the market or putting into service of transformers with a power rating of at least 1 kVA used in 50 Hz electricity transmission and distribution networks or for industrial applications. Called ECODESIGN Tiers 1 (2015) and ECODESIGN Tiers 2 (2021).

Our standard range of SANERGRID BDRSA retention tanks complies with French, European and international standards and recommendations concerning the retention of dielectric fluids, fire risk management, the management of contaminants and rainwaters in high-voltage substations and the protection of people and property.

- French standards NF C13-100 and NF C13-200, which prevent the electrical risks of overcurrents, earthing problems, fire risks, short-circuits and lightning, soil pollution and environmental pollution.

- Standard NF EN 61936-1, relating to the design and installation of electrical installations, which requires watertight retention representing 100% of the volume of oil used, and provides the necessary indications for pre-dimensioning retention volumes and surfaces, fire safety distances and systems, and rainwater management associated with the outdoor storage of hydrocarbons.

- CIGRE 23-07 and IEEE 980 recommendations on the use of fire suffocating covers for transformer pits and tanks, as well as guidance on the pre-sizing of indoor and outdoor retention pits and tanks.

- Our retention tanks are designed and manufactured in accordance with the European norms and standards of EUROCODE 3 (Calculation of steel structures).

- Our manufacturing plants are certified ISO 9001 for their quality management process and IS0 14001 for their environmental management process, and are all based in Europe to encourage short supply chains and limit carbon emissions.

- Our French and European sites enable us to guarantee that all our steel comes from European production, which is made up of over 50% recycled steel in order to limit the over-exploitation of resources and limit the carbon emissions linked to our manufacturing activities SANERGRID.

- Rainwater drainage and oil pollution for outdoor use:

Thanks to the SPI anti hydrocarbons filter system, the tank is empty most of the time and ready to receive hydrocarbons. In compliance with the French Water Act (decree 77-254), the water discharged from the tanks is not contaminated with more than 5 ppm of hydrocarbons, in accordance with standard EN 858-1 (“light liquid separation installations”).

SPI® filters are regularly tested by independent laboratories: SANERGRID Bureau Veritas report certified COFRAC I.D.: 003606/2776443/1/1/1 in 2015 (France), SPI Phoenix I.D. laboratory reports: AR67044 from 2002, 2004, 2005, 2009, 2018, 2022 (USA), TÜV report Nr 2432974 in 2016 (Germany), NUA report -Z-11895-1/1-2016. (Non-exhaustive list)

Our selection for you…