RIS2 Protective relay for oil-filled electrical transformers

0,00 €

Safety detector to protect your oil transformer

The RIS2 protection relay is a safety detector for distribution transformers. It is an essential accessory for protecting your oil transformer. It continuously monitors pressure, temperature, oil level and gassing conditions.

Description

Description

The transformer is an essential link in the electricity distribution network. In the event of a transformer failure (major overload, internal damage, etc.), the network upstream and downstream of the transformer must be protected by monitoring devices (alarm/shutdown) built into the protection relays. These may be of the DGPT2 (Gas, Pressure and Temperature Detection Relay), DMCR (Detection, Measurement and Control Relay) or RIS2 (Integrated Safety Relay) type.

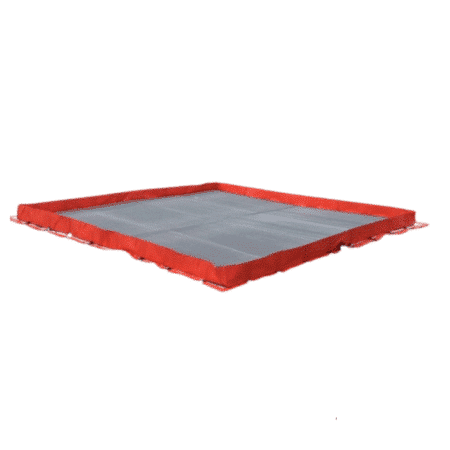

The RIS2 safety detector is the essential accessory for protecting your oil transformer, to ensure that it operates correctly. It consists of a robust plastic body, waterproof and resistant to extreme climates, with a series of instruments that constantly monitor operating conditions.

Like the DGPT2 or DMCR, the RIS2 monitors tank pressure from 100 to 500 mbar. This function measures the transformer’s internal pressure. When it exceeds a predefined level, the alarm circuit is triggered.

Thanks to its built-in thermometer, this relay indicates the internal oil temperature and the maximum temperature reached in the event of an internal fault or overheating. It contains two thermostatic switches, “T2” (ALARM) and “T1” (OFF), which trip at a preset temperature.

The visual sensor indicates any change in the gas or significant variation in the oil level. This is indicated by the position of the float between “MIN” and “MAX”. If there is a significant change in oil or gas level, the float stops at “MIN” and opens/closes the alarm circuit.

In order to control the gassing of the oil transformer, a detector closes/opens a circuit when the maximum volume of gas is reached (max. 170 cm3), and is triggered by small insulation failures.

Accessories and options

The RIS2 protection relay ensures the safety of oil transformers:

- Hydro-electric transformer

- Substation transformer

- Offshore wind transformer

- Renewable energy transformers

Technical data

Additional information

| Conditions of use | indoor, outside |

|---|

Use and maintenance

Installation tips :

- Before installing, remove the protective cap from the oil drain hole,

- Make sure the running surface is smooth and flat,

- Protect the RIS2 device from any subsequent painting operations,

- Install the RIS2 only after the transformer has dried,

- Switch off the supply voltage before working on the relay,

- Clean with a damp cloth. Do not use strong solvents or benzene,

- Do not remove the float from inside the relay.

Instructions for completing the device level :

The device is filled with oil exclusively by the transformer manufacturer at ambient temperature. Before switching on the transformer, make sure that the RIS2 relay is completely filled with oil. For various reasons, the oil may be below the set level. If the transformer is hot, due to the high ambient temperature or its own operation, the internal pressure may increase causing a visible drop in the oil level in the device chamber.

Refer to the user manual for further details.

The owner of the equipment is responsible for and liable for any failure to comply with good operating practice and for any failure to deal with anomalies and defects in the field.