HVIC Cleaning coating for high voltage insulators

0,00 €

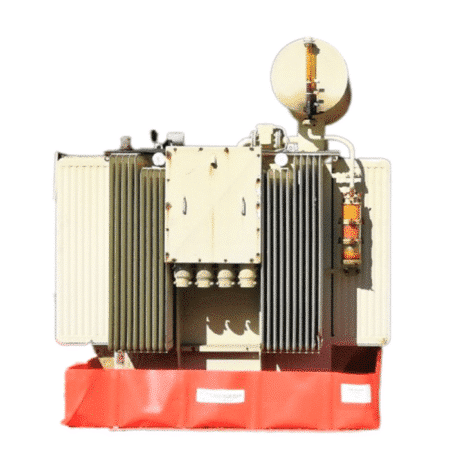

Midsun® RTV silicone rubber cleaning coating for high voltage insulators

Midsun®‘s HVIC coating is a unique silicone paint formula. This coating extends the life of your products and increases their reliability at a lower cost. It prevents excessive leakage currents, discharge elongation and arcing, minimising the need for maintenance.

Description

Description

The excellent performance of Midsun®‘s HVIC RTV (Room Temperature Vulcanizing) silicone rubber coating is due to its hydrophobicity and unique adhesion agents, with protective properties against flashover and electrical discharges. The hydrophobicity of the coating prevents the build-up of contaminants on the surface. It offers a long-term solution to breakdown problems. We offer turnkey solutions, which include the application of the coating to insulators installed by an OSHA-certified Midsun® staff member.

Midsun’s HVIC silicone resists UV radiation, temperature variations, corrosive environments and aluminium hydroxide pitting caused by arcing in dry strips. This coating is mainly used on polluted sites such as steelworks, cement works and quarries, as well as coastal and petrochemical sites.

The HVIC can be used to eliminate or reduce the frequency of the following operations:

- Regular cleaning of insulators

- Periodic lubrication

- Replacement of components damaged by electrical discharges

- Repair of the silicone coating or core in the case of composite insulators

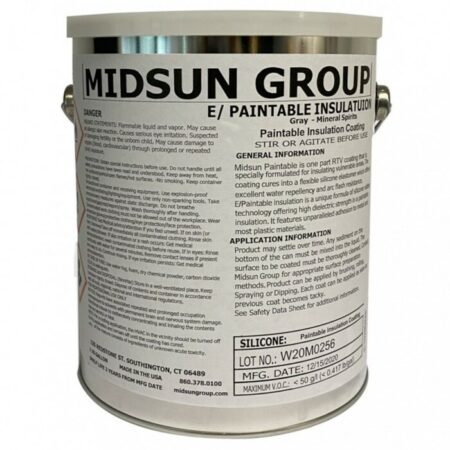

Description of Midsun® ‘s HVIC coating:

- Flash point: 18°C

- Dielectric strength: 35.9 kV/mm

- Dissipation factor at 100 Hz: 0.021

- Breaking and erosion resistance at 2.5 kV/min: 1000 hours

- Dielectric constant at 100 Hz: 3.85

- Relative density: 1.28

- Viscosity 3.5-5.5 Pa*s

- Coat thickness: 0.4 mm minimum

We offer a range of packaging options to suit your needs: aerosol cans, 3.7-litre jars and 19-litre buckets. Note that each 3.7 L can covers 8m² to 11m² with a two-coat application depending on the thickness of the film.

Midsun®‘s HVIC coating is guaranteed against electric arcs as soon as leakage currents are detected, when it has been applied by Midsun® Group personnel or under their direct supervision.

Contact us with details of your site and project requirements.

Accessories and options

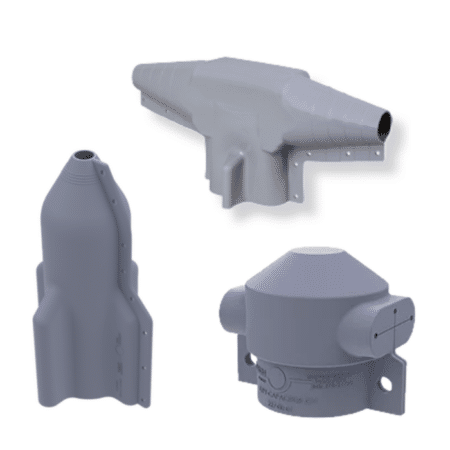

The products in the Midsun® range:

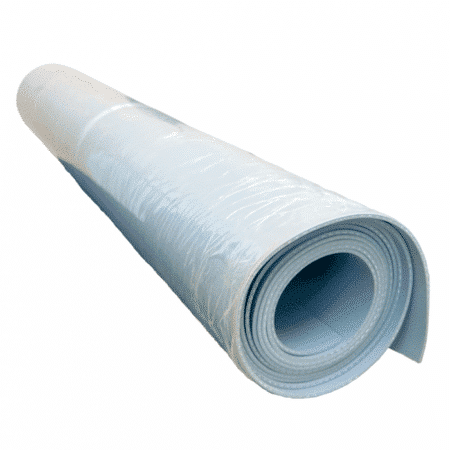

- Insulation sleeves for cables and stretched cables: E/FOURREAU range

- Self-fusing insulation tapes: E/TAPE range

- Cut-to-size insulation panels: E/PLAQUE range

- Standard and made-to-measure pre-formed protective covers: E/COVER range

- Disc-shaped barriers: E/BARRIER range

- Silicone insulating paint: E/PEINTISO range

- Anti-corrosion paint: SILPROCOAT range

Technical data

Additional information

| Conditions of use | outside |

|---|---|

| Material | Silicon |

Use and maintenance

Before installation:

- The surface of the insulator to be treated must be clean and dry.

- Dry blasting with granules of walnut shells or corncobs may sometimes be necessary, for example, in insulators installed in cement factories or other highly polluted environments. Dry blasting is also recommended for insulators that have been greased.

Installation:

- Application temperature range: 0 – 50 °C

- There are various methods of applying the coating: by brush, dip or spray. Aerosol cans are recommended for treating small numbers of insulators.

- In principle, one to three coats are enough to achieve the recommended minimum thickness of 0.4 millimetres (0.015 inch).

Refer to the user manual for further details.

The owner of the equipment is responsible for and liable for any failure to comply with good operating practice and for any failure to deal with anomalies and defects in the field.

Documentation

Our selection for you…

-

E/TAPE Insulating Tape for Bird-Safe Protection

0,00 € -

E/PEINTISO Silicone insulating paint for bird protection

0,00 € -

E/COVER Removable insulating covers for bird protection

0,00 € -

E/FOURREAU Insulating bird protection sheath for live cables

0,00 € -

E/PLAQUE Silicone cover for bird protection

0,00 € -

E/BARRIER Thermoplastic disc for bird protection

0,00 €