VIBER-80 Vibration-damping system to 80% for transformers with wheels

0,00 €

Up to 80% vibration damping for electric transformers with wheels

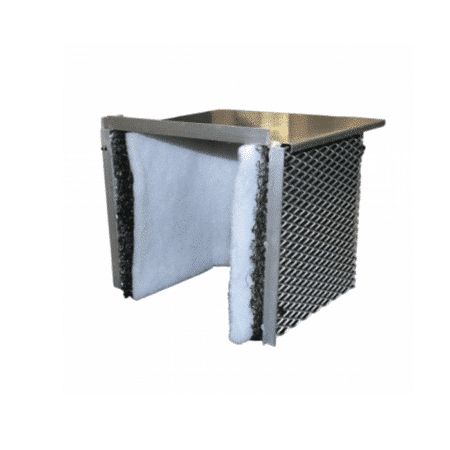

VibeR-80 is a range of anti-vibration mounts that are completely integrated into the wheels of electrical transformers, reducing up to 80% of vibrations. These silentblocks have been developed to provide high anti-vibration performance at transformer excitation frequencies, depending on their weight.

Description

Description

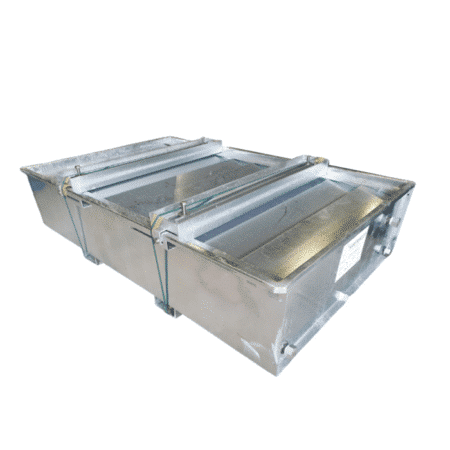

When electric transformers are in operation, they emit a characteristic noise from the vibrations of the laminations they contain. This vibration comes from the 50 Hz alternating current that flows through them, which has a fundamental vibration frequency and several corresponding harmonics of vibration at 100 to 200 Hz. Depending on the load used, the design and the age of the transformer, these vibrations can increase over time. In addition, depending on the installation site, these vibrations may enter into resonance with the frame.

To dampen the noise generated by oil-filled or dry-coated electrical transformers when they are in operation, we have designed the SanerVib® range. This is a range of low-frequency silentblocks specially developed to provide high anti-vibration performance at transformer excitation frequencies. The VibeR-80 series is designed to reduce vibrations by up to 80%.

Description of the VibeR-80 range:

- Classic 4-support configuration

- Stainless steel damper spring

- Metal design with a modulus of plasticity that varies very little over time, unlike other plastic or elastomer solutions on the market, which have to be changed regularly.

- Reinforced surface treatment so that ageing is close to the life of the transformer.

- All VibeR99s are made of painted steel, category C2, with a superior anti-corrosion treatment (galvanisation or stainless steel on request).

- Midnight blue as standard, other colours available on request

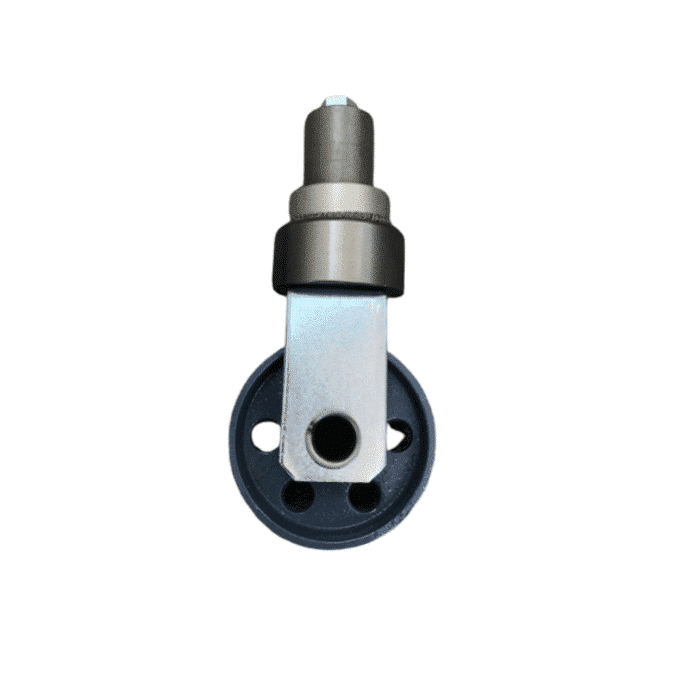

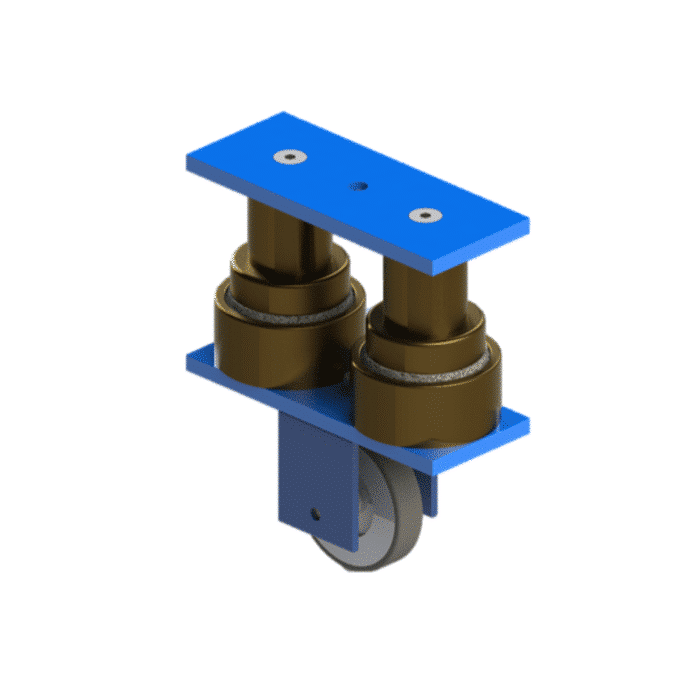

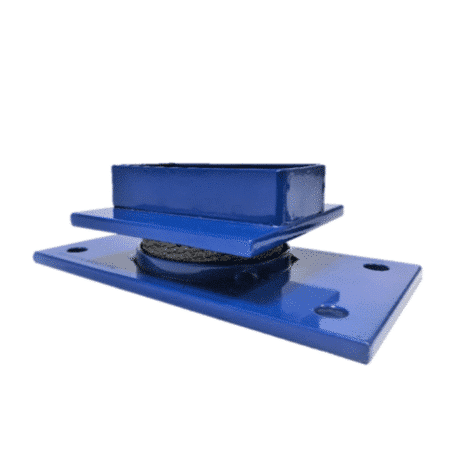

The VibeR-80 is a silentblock specially designed to be integrated directly into the transformer, above the roller. Depending on the load to be supported, it consists of 1 or more damping elements:

- Single VibeR-80 up to 300 kg (ref. VibeR99-1200) and up to 750 kg (ref. VibeR99-3000)

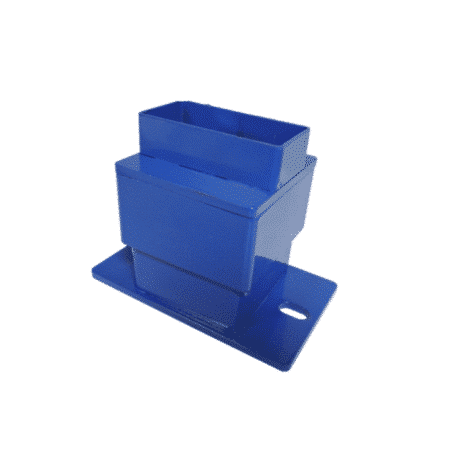

- Double VibeR-80 from 500 to 1500 kg (ref. VibeR99-6000)

Details of the VibeR-80 range:

- VibeR-80-1200: Length: 8.8 cm / Width: 8.8 cm / Height: 12 cm / Weight (set of 4): 12 kg

- VibeR-80-3000: Length: 8.8 cm / Width: 8.8 cm / Height: 12 cm / Weight (set of 4): 14 kg

- VibeR-80-6000: Length: 20 cm / Width: 8.8 cm / Height: 14 cm / Weight (set of 4): 24 kg

Accessories and options

The SanerVib® range comprises several references depending on the support load, wheel dimensions, type of base plate, required attenuation, etc. Please contact us with the characteristics of your site and your requirements for the anti-vibration system.

Depending on the configuration of your project, the SanerVib® range is available in several versions:

- For your transformers with wheels: SanerVib 80 range (80% reduction) SanerVib 99 range (99% reduction)

- Instead of wheels, an anti-vibration block can be installed on your transformers: SanerVib 80-SG range (80% reduction) and SanerVib 99-SG range (99% reduction).

- For easy installation on your rolling electrical transformers with an integrated slope, absorbing 80% of vibrations: SanerVib 80-SL range

- For special applications, contact us: SanerVib-SP range

Technical data

Additional information

| Conditions of use | indoor, outside |

|---|---|

| Material | Stainless steel, steel |

| Transformer adapter | with rollers |

| Vibration attenuation | 80% |

Use and maintenance

Before installation:

It is essential to choose the right reference for your site, taking into account the width of your wheel (so that it fits into the upper support and cannot be moved) and the weight of your transformer (so as not to exceed the recommended compression range).

Installation:

- For simple VibeR80s, an M10 x 80 screw passes through the damper, enabling it to be fixed directly to the transformer’s beam or U-profile,

- For double Viber80s, an M10 hole centred on the upper plate is used to attach the shock absorber to the beam, while a second M10 hole centred on the lower plate is used to attach the wheel using an M10 x 25 screw.

Screws and bolts are included, but not the rollers (which may be available as an option).

Maintenance:

The treatment of SanerVib® has been reinforced, so unlike other solutions, they do not need to be replaced.

Refer to the user manual for further details.

The owner of the equipment is responsible for and liable for any failure to comply with good operating practice and for any failure to deal with anomalies and defects in the field.

Additional information

Storage facilities for high-voltage substations in contact with polluting products must comply with the standards and laws in force.

The SanerVib® range has been designed to isolate these vibrations generated by the magneto-constriction of transformers, and in particular its fundamental excitation frequency of 50 Hz and its harmonics of 100 to 200 Hz. All SanerVib® silentblocks have been tested in specialist SilentFlex® laboratories.

You may also like…

-

SANERVIB-80 Anti-vibration mounts up to 80% for transformers with wheels

0,00 € -

SANERVIB-99-SG Anti-vibration mounts up to 99% for impellerless transformers

0,00 € -

SANERVIB-99 99% Anti-vibration mounts for transformers with wheels

0,00 € -

SANERVIB-80-SL Vibration damper to 80% with rolling slope

0,00 € -

SANERVIB-80-SG 80% Anti-vibration pads for impellerless transformers

0,00 €