GALVAGRID® TANK™ Galvanic protection of metallic bunds

0,00 €

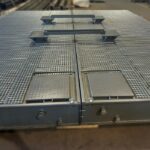

Galvanic protective coating for SANERGRID metallic retention tanks in saline environments

GALVAGRID® room-temperature galvanizing coating is an organic formula of 99.995% pure zinc, forming an electrochemical bond. This technology applied to our hot dip galvanizing on SANERGRID’s and SONEC’s tanks enables us to form an anticorrosion system known as GALVAGRID® DUPLEX™ equivalent to C5HV protection in a saline ambiance.

Description

Description

GALVAGRID® TANK™ room-temperature galvanizing coating provides cathodic protection up to C5H or C5HV or CX equivalent in saline environments. The GALVAGRID solution doubles the standard service life of hot-dip galvanized steel retention tanks for SANERGRID transformers.

GALVAGRID® TANK™ is used in areas where corrosive and aggressive factors unfavorable to hot-dip galvanizing are encountered, or to double the service life of standard hot-dip galvanizing on our retention tanks. Food approved by the Canadian Food Inspection Agency (indirect contact). This technology was used exclusively by NATO military forces from 1954 to 2003. Since 2003, we have had numerous international references in the private sector, in energy, shipping, petrochemicals, transport, etc. SYNERDIS is the European representative for the electrical energy sector.

The advantages of GALVAGRID® TANK:

- GALVAGRID is not a paint: this galvanic coating enhances the self-healing properties of our hot-dip galvanized tanks.

- GALVAGRID is extremely resistant to scratches, abrasion and rubbing, unlike a paint-type coating.

- Can be applied in the workshop or directly on site.

- Follows thermal expansion and metal deformation, without cracking.

- Can be overcoated with most paint products (mainly epoxies and urethanes): it can therefore be used as a primer.

- Is the only technology capable of bonding perfectly with old hot-dip galvanizing and/or metallizing and then recharging the cathodic protection potential: this is known as room-temperature Galva recharging.

- Even extends the resistance of the corrosion protection to a C5H equivalent on new hot-dip Galva: DUPLEX™ SYSTEM.

Contact us with your site information and project requirements.

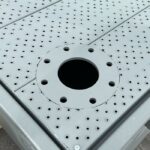

Description of GALVAGRID® RUST-ANODE™ TANK:

- Zinc content: 87% + 5% (weight) pure zinc in the dry layer

- Zinc purity: ± 99.995% purity

- Ready-to-use: single-component coating

- Color: Matte light gray RAL #7005

- Safety: Non-toxic and non-flammable when dry

- Specific gravity: 2.45 Kg/dm3 ± 5%.

- VOC (solvents): 285 grams/liter + 10

- Application on: SANERGRID hot-dip galvanized steel retention tanks in our plants

- Flash point: 52° C

- Thinner: GALVASOLV PRIM

Accessories and options

GALVAGRID® is suitable for a wide range of applications:

- Electrical towers and telecommunication towers: GALVAGRID® PYLON

- Metal and steel structures and superstructures: GALVAGRID® SUBSTATION

- Metal and steel bridges, footbridges, and girders: GALVAGRID® INFRASTRUCTURES

- Marine infrastructure and port facilities: GALVAGRID® OFFSHORE

Technical data

Additional information

| Conditions of use | outside |

|---|---|

| Material | Zinc |

| Application support | Metallic bunds |

Use and maintenance

Application of GALVAGRID TANK:

GALVAGRID BAC is applied directly in the factory by our approved and authorized teams for the application of GALVAGRID. All our tanks treated with GALVAGRID ambiance C5 are delivered with:

- An application report,

- Zinc thickness measurement,

- Hot dip galvanizing certificate,

- A manufacturer’s certificate of conformity.

Additional information

Tests carried out in accordance with current international standards:

- ASTM D5894: Cyclic corrosion (excellent)

- ASTM G44-99: Immersion corrosion (< 0.03%)

- ASTM D4060-14: Abrasion (116 mg)

- ASTM D4541: Perpendicular pull-off (1775 psi)

- ASTM D3359: Adhesion (100%)

- ASTM D3363: Hardness (excellent – 5H)

- ASTM D2794: Impact (no cracking)

- ASTM D522: Strength (1/pc), Elongation (15%)

- ASTM G154: UV resistance

- ASTM GB117 and ISO 12944-6/7253: Salt spray resistance