POSITRON COMPOSITE HV composite insulator tester

0,00 €

Composite insulator testers for high-voltage lines

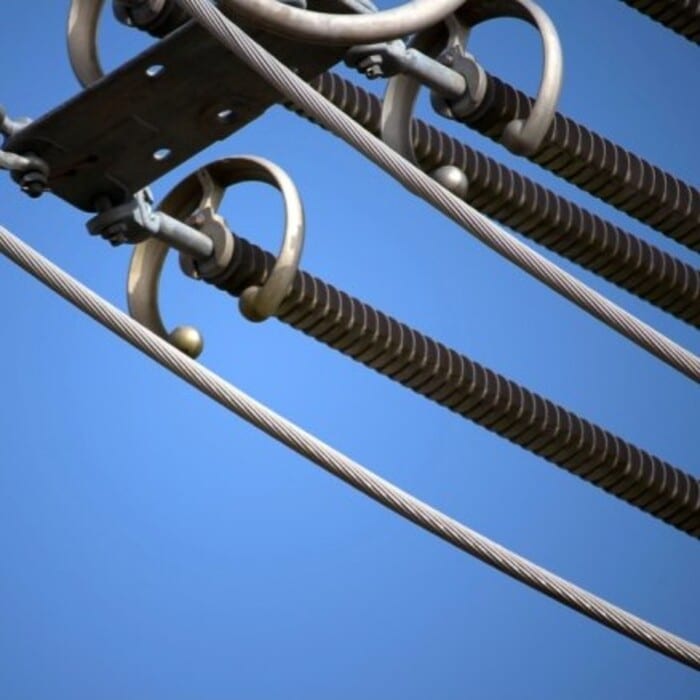

The POSITRON® high-voltage insulator tester can be used to test a large number of composite high-voltage insulators on power lines, electricity pylons and transmission and distribution poles.

Description

Description

Breakdowns due to insulator failure are costly. In addition, live working requires insulators to be in good condition for the safety of line workers and high-voltage workers. A critical failure can cause long-term damage as well as material and financial losses. Pollution, salt spray, dust, wear, shocks or micro-defects can dramatically alter insulator quality.

Whether made of porcelain, glass or composite (silicone), the quality of an insulator is a determining factor in the robustness of your electrical installation.

In a high-voltage electrical substation, many items of equipment contain insulators, such as switchgear, measuring equipment and electrical connections: power transformers, bushings, circuit breakers, disconnectors, current transformers, voltage transformers, bushings, etc.

POSITRON Insulator Testers are revolutionary, lightweight, easy-to-use tools that record faults and hazardous conditions on suspended insulators, sub-station circuit breakers, bushings and live surge arresters. POSITRON insulator testers represent a major advance in insulator maintenance.

POSITRON COMPOSITE testers are the only devices capable of detecting faults on composite or silicone insulators.

Description of POSITRON COMPOSITE:

- The instrument detects obvious defects or enables early detection

- Records faults, up to 15,000 readings.

- Operates on undervoltage insulators from 69 kV to 1,000 kV.

- Available in 50 Hz or 60 Hz versions.

- Microelectronic technology: Test results are acquired and stored by a built-in microprocessor, allowing readings to be downloaded to any laptop for graphical display, analysis and long-term comparison.

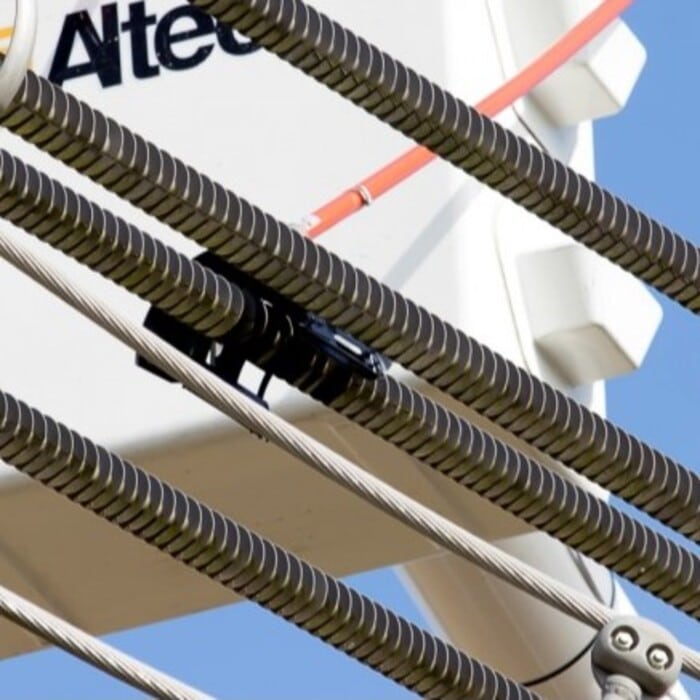

- Compatible with standard field equipment: All units include a universal mounting bracket compatible with industry-standard high-voltage booms.

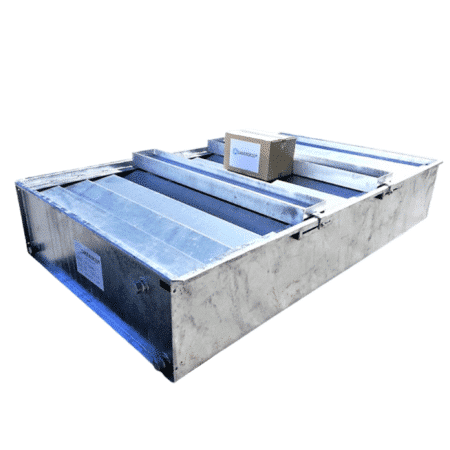

- Lightweight and durable: POSITRON insulator testers are lightweight (less than 1.6 kg), durable and designed to withstand the specific conditions of use. They come in a robust carrying case for maximum portability and durability.

POSITRON COMPOSITE is reliable and certified by various electricity companies around the world, including EDF and RTE in France.

Contact us with details of your site and project requirements.

Accessories and options

Whether made of porcelain, glass or composite (silicone), the quality of an insulator is a determining factor in the robustness of your electrical installation.

POSITRON insulator testers are available in several references to cover all your needs:

- Glass and porcelain insulators : POSITRON GLASS AND PORCELAIN

- Universal insulators for substations (glass, porcelain and composite) : POSITRON SUBSTATION

- The insulator tester can be mounted on a drone to avoid working at height under voltage: POSITRON DRONE

Technical data

Additional information

| Type of insulator | Composite |

|---|

Use and maintenance

The operational integrity of high-voltage insulators is a priority, especially when you consider that a damaged or electrically defective insulator can lead to network failure, serious injury or death of personnel in the vicinity of the fault. POSITRON insulator testers represent a major advance in insulator maintenance. They enable high-voltage insulators to be assessed safely and reliably. Simply slide the tester sled along the insulator or insulator chain and the results are automatically processed and accessible.

How do we do it?

Electric field methodology: The POSITRON insulator tester can be used to assess and diagnose porcelain and composite insulators.

The insulator tester measures the alternating electric field surrounding porcelain and composite insulators. The field is proportional to the voltage across an insulator and drops at the location of the conductive fault. The electric field is read and stored for each disc or string.

Why the electric field?

Unlike detection by infrasound or hot spot measurement, the measurement does not depend on the firing zone. What’s more, electric field measurement makes it possible to measure fault trends or floating faults that are not detected by traditional methods, and to establish trends by insulator over time. Finally, POSITRON testers are the only devices capable of detecting defects on composite insulators.

How does it work?

Procedure:

- The operator positions himself and presses the push-button on the probe and recorder.

- The tester is placed on the chain a few insulating discs before the end of the insulator chain.

- The tester is returned to the start of the chain and held still for at least 10 seconds until a long beep is heard.

- The tester is slid to the end of the chain line, then back to the starting point. The buzzer sounds each time a playback is made on each isolator disc.

- The tester is removed from the chain, ensuring that a continuous sound is audible to indicate that the analysis has been successful. By pressing the push button, the operator sends the data, which is immediately visible on the PC screen and stored in the database.

Refer to the user manual for further details.

The owner of the equipment is responsible for and liable for any failure to comply with good operating practice and for any failure to deal with anomalies and defects in the field.