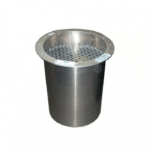

PETRO-BARRIER™ PUMP PTB-24 Anti-hydrocarbon filtration pumped system

0,00 €

Cartouche séparateur hydrocarbures, par pompage, longue durée

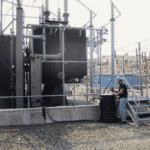

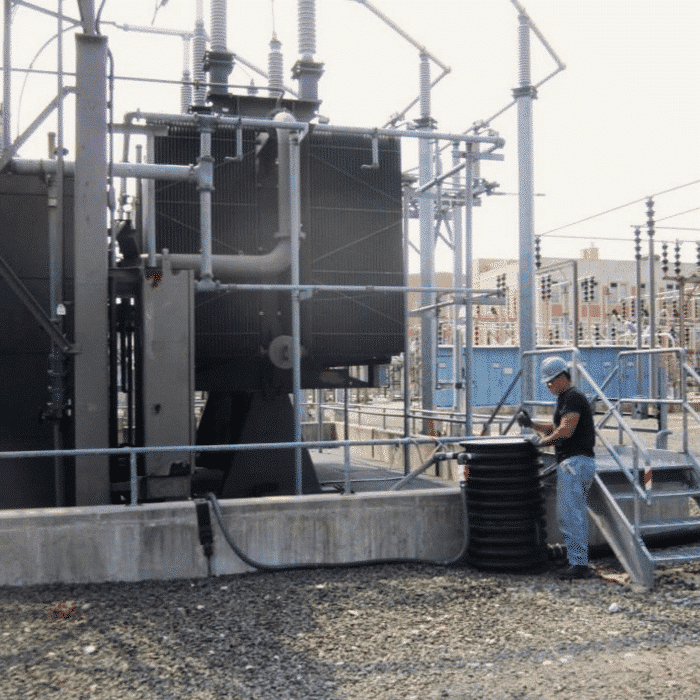

The PETRO-BARRIER™ PUMP PTB-24 is a system for filtering large volumes of rainwater contaminated with dielectric oils for large transformers’ retention tanks and pits. Its self-locking system traps harmful hydrocarbons, preventing soil pollution. Its oleophilic and hydrophobic polymer component permanently traps hydrocarbons.

Description

Description

The PETRO-BARRIER™ PUMP PTB-24 is a system specially invented by SPI® in the 1990s for easy adaptation to all types of retention tanks and pits. It provides continuous drainage water filtration for large volumes, while trapping harmful hydrocarbons: it therefore prevents soil pollution in accordance with EN 858-1 and the Water Act, with a discharge rate of less than 5ppm. It also complies with paragraph 471 of NF C13-200 (“All precautions must be taken to ensure that the recovery tank does not fill with water or that water is evacuated“). Our filters are regularly tested in independent laboratories, when new, in half-life conditions and after their recommended period of use (see Additional Information tab).

In the event of a major hydrocarbon spill, the component reacts and forms a plug, preventing any fluid from spilling into the environment. It is a self-locking system, operating without any mechanical parts or electrical connections.

The PETRO BARRIER™ PUMP has two separate chambers: one for fluid intake at the top, the other for filtration at the bottom provided by an SPI® PETRO BARRIER™ anti hydrocarbons filter water cartridge.

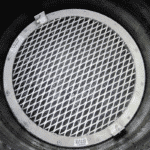

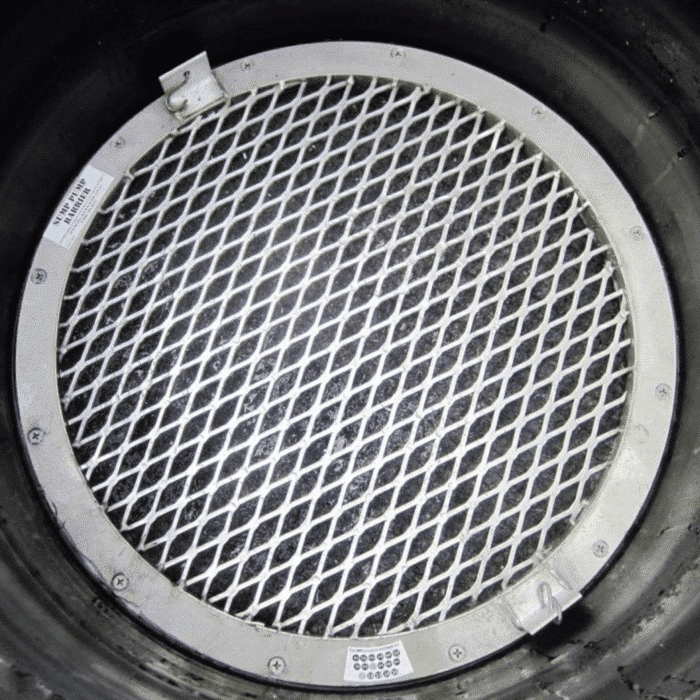

Pre-filtration of the inlet water is vital to avoid blocking the PETRO BARRIER too frequently with dust. Pre-filtration takes place at 3 specific points:

- The first, large mesh, is made with a pre-filtration cage around the pump (not included).

- The second, smaller one is done through external pre-filters at the inlet of the PETRO BARRIER™ PUMP

- The third takes place in the internal pre-filtration chamber of the PETRO BARRIER™ PUMP

Description of the PETRO-BARRIER™ PUMP PTB-24:

- Made from rigid PVC with UV protection for extra strength and durability.

- Hydrophobic, oleophilic polymer component: permanently locks in hydrocarbons.

- A 1.5″ pipe at the top for water to enter the intake chamber

- A 4” pipe at the foot of the pump for water drainage

- A 2″ return pipe is used to return contaminated water to the retention tank, preventing excess pressure in the intake chamber. This safety system enables the plant to operate in a closed cycle in the event of a leak, preventing hydrocarbons from being pumped out while a response team seals the leak and cleans the retention tank.

- Supplied with elbows and clamping collars for all pipes, 1 internal pre-filter replacement by default, 1 flow control valve and 1 aluminium pre-filter support structure.

- Length: 110 cm / Diameter: 73 cm / Weight: 70kg

- Approximate filtered flow rate (*): approx. 110 L/min / Approximate saturation (*): 15 L / Recommended change (*): every 5 years

(*) Depending on the conditions of use at each site, depending on the quantity of traces of hydrocarbons filtered by the cartridge, the regularity of maintenance of the tank/pit/prefilters, etc. Conditions of use for which SANERGRID® and SPI® cannot make any commitment.

SPI filters have been recognised for over 30 years for their high reliability, extreme robustness and longevity, even in the most difficult conditions: resistance to hot transformer oils (>100°C), water emulsified with dielectric oil, high resistance to ultra-violet rays and thermal amplitudes, eco-designed to reduce the quantity of materials and CO2 during the manufacturing process.

The pump and pump pre-filtration grille are not included in the standard PETRO BARRIER POMPE PTB-24 pack. Please contact us for further information.

Accessories and options

The PETRO BARRIER™ range is available in several references of filters, pre-filters and pumps to equip the PETRO-BARRIER™ PUMP PTB-24:

- Active cartridge: PETRO-BARRIER™ PTB-C-24

- Internal coarse particle prefilter: PETRO-BARRIER™ PTB-DF-24

- Internal small particle prefilter: PETRO-BARRIER™ PTB-SF-24

- External small particle prefilter: PETRO-BARRIER™ PFE-MP

- Pump pre-filtration cage: PETRO-BARRIER™ PFE-PUMP

- Standard 220V pump: PETRO-BARRIER™ PUMP-PTB

- 5” inlet pipe: PETRO-BARRIER™ IN-P-1.5

- 2” overflow pipe : PETRO-BARRIER™ OVR-P-2

- 4” outlet pipe: PETRO-BARRIER™ OUT-P-4

For special volumes or flow rates, please contact us. There are many alternatives:

- PETRO-BARRIER™ SPECIAL PUMP

- DOUBLE PTB on single pump

Contact us for more information.

Technical data

Additional information

| Weight | 70 kg |

|---|---|

| Dimensions | 110 × 73 cm |

| Material | Aluminium |

| Conditions of use | indoor, outside |

| Filtration | Dielectric oils, Hydrocarbons |

Use and maintenance

All industrial equipment or storage units containing hydrocarbons must be fitted with retention tanks.

Installation:

- Vertical installation outside the retention volume fed by a pump in the retention pit.

- The internal and external pre-filters are simply screwed on and off through the opening in the top cover of the PETRO BARRIER PUMP.

Maintenance:

- SPI filters are sensitive to sludge and impurities carried by the water, which can considerably reduce the flow rate or even block the filter. Good pre-filtration is therefore essential to protect the filter inlet, and should be checked regularly. The pre-filter should be washed with clean water as often as required by the place of use, the frequency of rinsing depending on the quantity of impurities carried to each drainage point.

- To keep track of your filters and replacement schedules, SPI products have a batch serial number corresponding to the batch of active ingredient tested and approved by the manufacturer. So you too can track your filters and recommended replacement dates simply by visual inspection.

- At the end of their life, the filter and pre-filter should be disposed of as conventional hydrocarbon waste under code [150202*].

For your specific needs in terms of traceability and automatic reminders of your maintenance dates, SANERGRID® can set up a unit tracking system for you, in return for a maintenance contract with one of our national partners.

Additional information

The PETRO-BARRIER® PUMP range, part of the SPI® filter technology, is the European benchmark for hydrocarbon-contaminated rainwater filter cartridges for small-volume retention. It is the only filter on the market that has been validated for over 30 years by the largest French and European manufacturers (EDF, ENEDIS, SNCF, SCHNEIDER, RTE, ABB HITACHI, SIEMENS, IBERDROLA, NATURGY, REE, EDP, ENEL, IREN, TERNA, E-ON, RWE, VATTENFALL, ELIA, ESB, SCOTTISH POWER, NATIONAL GRID, NETWORK RAIL, UK PN, BRITISH PETROLEUM, TOTAL ENERGIE, BASF, BAYER, ELES, CERN, ITER, VOLVO, DEUTSCHE BAHN, ADIF, SNCB, REPSOL, etc? non-exhaustive list).

Rainwater drainage and hydrocarbon pollution: thanks to the SPI anti hydrocarbons filter system, the tank is empty of water most of the time and ready to receive hydrocarbons. In compliance with water legislation, the water discharged from the tanks is not contaminated with more than 5 ppm of hydrocarbons, in accordance with standard EN 858-1 (“light liquid separation installations”).

SPI® filters are regularly tested by independent laboratories: SANERGRID Bureau Veritas report certified COFRAC I.D.: 003606/2776443/1/1/1 in 2015 (France), SPI Phoenix laboratory reports I.D.: AR67044 in 2002, 2004, 2005, 2009, 2018, 2022 (USA), TÜV report Nr 2432974 in 2016 (Germany), NUA report -Z-11895-1/1-2016.

Documentation

Videos

Our selection for you…

-

PETRO-BARRIER Hydrocarbon filter for drainage of large retention areas

0,00 € -

PETRO-BARRIER™ PTB-C-24 Internal filter exchange for PETRO BARRIER

0,00 € -

PETRO-BARRIER™ PTB-SF-24 Internal fine particle prefilter for PTB-24

0,00 € -

PFE-PWF Pleated pre-filter for PFE-MP filtration system

0,00 € -

PETRO-BARRIER™ PTB-DF-24 Internal coarse particle prefilter for PTB-24

0,00 €