TRFLEX® SUPER ECO Flexible storage berm for chemicals products

0,00 €

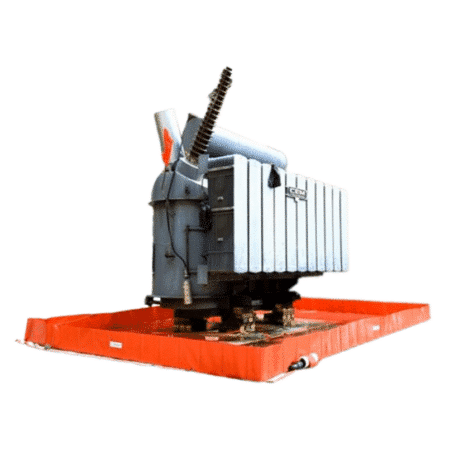

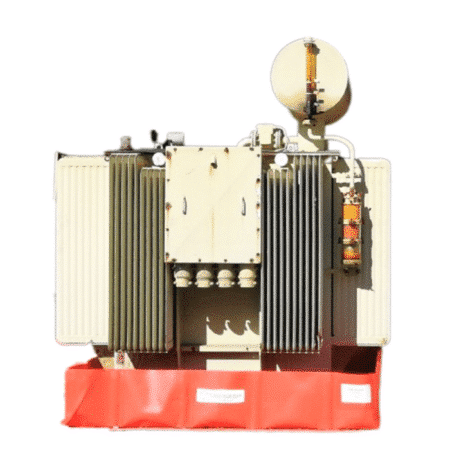

Storage tank for leaks of industrial pollutants

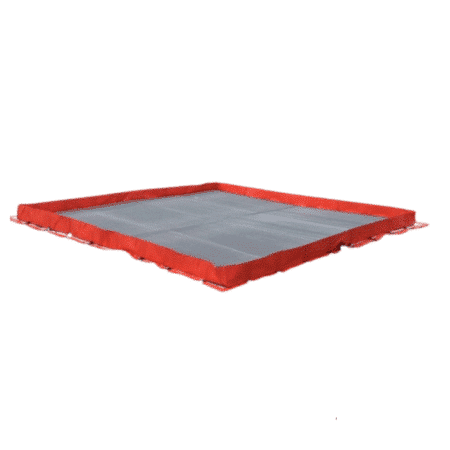

The standard TRFLEX® SUPER ECO range of ultra-strong flexible retention tanks has been designed to contain polluting products for short periods and avoid contamination of the surrounding water or soil. With its galvanized angle-bracket structure, our unique process of double ultrasonic welding of ultra-reinforced 1670 DTEX two-way internal weave tarpaulin, and double PVC induction with anti-UV treatment at over 900 g/m² have made TRFLEX SUPER ECO one of the leading references on the European market.

Description

Description

How can you create a simple, fast, and effective temporary storage area for short to medium-term periods to contain pollutants from industrial equipment or machinery? SANERGRID’s TRFLEX SUPER ECO range is the answer to this problem, thanks to its flexible retention tanks and their highly technical features, capable of withstanding severe mechanical and chemical stress.

The TRFLEX SUPER ECO range is made up of 3 distinctive elements:

Long experience of TRFLEX technology

SANERGRID’s TRFLEX SUPER ECO flexible tarpaulin for transformer storage is the direct result of long experience in dealing with oil spills and managing oil pollution on the high seas. SANERGRID has reengineered this ultra-resistant tarpaulin, which is mechanically, chemically, and UV-treated, to adapt perfectly to the constraints of electrical transformer storage.

- Reinforced PVC tarpaulin with double internal weft in high-tenacity 1670 DTEX polyester for enhanced mechanical resistance to tearing, puncturing, cutting, and tearing.

- Double-sided vinyl (PVC) tarpaulin, resistant to hydrocarbons and ultraviolet rays, with a total weight of over 900 g/m² for enhanced resistance to abrasion, sunlight, and hydrocarbons.

- Unlike traditional tarpaulins on the market, the double-sided induction process provides double retention security: in the event of a non-through cut on one side, the opposite wall continues to act as retention.

- All our welds are made using a unique double-sided ultrasonic welding process, which makes the welds extremely robust and guarantees complete watertightness of the TRFLEX® flexible berm.

100 mm to 500 mm high bracketed tarpaulin support structure

- TRFLEX SUPER ECO tarpaulin sleeves are welded in our factories all around the pan, to accommodate the feet that hold the vertical walls in place. For the TRFLEX SUPER ECO range, this angled metal structure is made of hot-dip galvanized steel by default. Aluminum or stainless steel available on request.

- All our TRFLEX retaining structures have been sized and tested by our factory to maintain their retention integrity up to 120% of their communicated nominal volume.

Protection against abrasion, puncture, and cuts

The TRFLEX ECO, SUPER ECO, ECO+ and REFOR ranges are supplied with 2 layers of GEOGRID™ protective geotextile, a special anti-abrasion material made of polypropylene reinforced with polyester.

- One covering 110% of the surface of the planter, to be placed under the planter to protect it from ground roughness and, above all, to make it easier to place the tarpaulin without slipping.

- The other 50% of the surface of the tray to be placed in the tray, to protect against scratches and punctures during equipment installation.

- Finally, for simple on-site repair, all our TRFLEX bins® ECO, SUPER ECO, ECO+, MAINTENANCE, ECO-TRUCK™ and REFOR come with a tarpaulin repair kit with patch and glue in the event of punctures or tears smaller than 10 cm.

Please note: all our low rainwater drainage points are between 30 and 50 mm from the ground by default. It is normal to have a residual water level in the tanks. We recommend raising your water-sensitive equipment several centimeters above ground level, using planks, wooden wedges, or concrete beams. For specific low point requirements, please contact us.

Accessories and options

The TRFLEX range also includes several accessories to suit your needs:

- Anti-hydrocarbon cartridges Kit PETRO PIT PVC and KIT PIPE PVC, when used outdoors to allow continuous drainage of rainwater.

- Additional protective geotextile layers GEOGRID™

- Steel load distribution plates

- Transport and storage bag

- Stackable hard cases for secure storage and transport of your TRFLEX products

- ECOROLL™ anti-puncture treads for heavy machinery

- Prefabricated concrete beams to raise your machine by a few centimeters if the equipment cannot withstand exposure to water

- Ballast bags for ballasting bins in windy areas or if there is a significant delay between the deployment of the bin and the installation of the material to be stored in the bin.

- CAMFLEX™ communications hoses to connect multiple TRFLEX® together.

We have a range of references to suit your flexible retention and temporary storage requirements:

- For temporary retention with low mechanical stress, short duration, and frequent reuse with a lighter tarpaulin: TRFLEX-ECO™ range

- For temporary retentions with higher mechanical stress, short to medium durations and frequent reuse with a heavier tarpaulin: TRFLEX-ECO+™ range

- For medium to very long-term storage applications the TRFLEX-REFOR™ range with a double reinforced tubular structure.

- For storing your trucks and tankers or rolling heavy machinery in the bin: TRFLEX-TRUCK™ range with special bearing races.

- For the storage of machinery containing hydrocarbons with an anti-slip maintenance surface: TRFLEX-MAINTENANCE™ range.

For permanent or semi-permanent storage, we recommend the TRT and TRT MODULO ranges, as well as concrete pits fitted with our SKID PIPE, STORM BARRIER and PETRO BARRIER POMPE drainage systems.

Once the leak has been contained, the pollutants can be absorbed using our anti-pollution absorbent kits. Made up of pads, pillows, and sheets, they effectively absorb liquids directly into the TRFLEX SUPER ECO flexible berm.

Technical data

Additional information

| Conditions of use | indoor, outside |

|---|---|

| Material | PVC |

| Type of bin | Flexible |

Use and maintenance

Before installing the berm:

- Ensure that the installation surface is smooth, flat, clean and large enough to accommodate the flexible retention tank and transformer, to avoid pinching and pressure points.

- We recommend adding at least one layer of geotextile before unfolding the tarpaulin (supplied as standard).

- If bins are stored outdoors, they must be emptied regularly, and not handled with water inside.

Installing the berm:

- Unfold the flexible berm at the desired storage location on the layer of geotextile supplied with the berm.

- Place your equipment on the geotextile previously installed at the support points, or on the runways/load distribution plates to avoid punching.

- Unfold the tray walls and insert the brackets into the welded sleeves around the edges.

- Secure or weight the bin to the ground to prevent tearing and lifting during windy episodes if you do not place the equipment in the bin within moments of setting up the bin.

Maintenance:

A regular visual inspection of the equipment is required for the following points:

- Tightness at wall penetrations, accessories and/or plugs correctly screwed in.

- Integrity of bin walls, absence of deformation or damage (knocks, impacts, cuts, tears, cracks, etc.).

- Check that rainwaters are flowing properly through the filters: in the event of clogging, be sure to clean the pre-filters, or change the filters if they are saturated or have exceeded their recommended service life.

- It is essential to carry out a visual inspection after each period of strong wind.

- The frequency of these checks depends on the constraints of each site, depending on its degree of corrosion, soiling, presence of organic matter, etc.

Please refer to the user manual for further details.

Failure to follow good operating practices and to deal with field anomalies and defects is the responsibility of the equipment owner.

Additional information

Storage facilities for high-voltage substations in contact with pollutants must comply with current standards and legislation.

The road transport structures used are in line with the recommendations for the transport of dangerous goods, as set out in the ADR.

Regarding retention tanks and the risk of soil pollution, our tanks comply with European standards:

- NF C13-100 and NF C13-200, which prevent the risk of overcurrent and grounding problems. They protect people from direct or indirect contact with conductors, and electrical installations from fire risks, short-circuits and lightning.

- NF EN 61936-1, relating to the design and installation of electrical installations, which requires watertight retention of 100% of the volume of oil used.

Rainwater drainage and oil pollution:

Thanks to the SPI anti hydrocarbons filter system, the tank is mostly empty of water and ready to receive hydrocarbons. In compliance with French water legislation (decree 77-254), the water discharged from the tanks is not contaminated with more than 5 ppm of hydrocarbons, in accordance with standard EN 858-1 (“light liquid separation plants”).

SPI® filters are regularly tested in independent laboratories: please refer to the SPI® ranges.

You may also like…

-

TRFLEX® -REFOR Flexible storage berm with reinforced tubular structure

0,00 € -

TRFLEX-ECO+ Flexible storage berm for high mechanical constraints

0,00 € -

TRFLEX® ECO Flexible storage berm for moderate mechanical constraints

0,00 € -

Emergency anti-pollution absorbent kit

0,00 € -

TRFLEX® ECO TRUCK™ Flexible storage berm for rolling stock

0,00 €