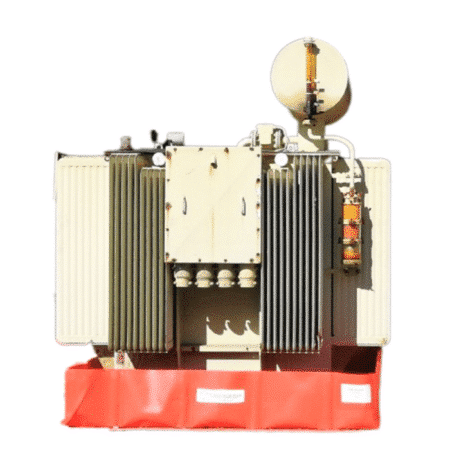

ETRA SUBSTATION Oil-filled power transformer

0,00 €

Kolektor ETRA power transformer, elevator, oil immersed, for electrical substations

Range of mineral oil power transformers from 10 to 500 MVA and up to 420 kVA, for power substations; custom-made power transformers manufactured in Europe.

Description

Description

Kolektor ETRA supplies oil-filled power transformers up to 500 MVA and voltage up to 420 kVA.

For step-up and step-down power transformers, as well as for production transformers in electrical substations, we pay particular attention to reducing the transformer’s noise level, as well as ensuring very low load and no-load losses. We also consider the dimensioning of conductors and insulating materials to cope with production peaks linked to hydroelectric turbines, and the effects of overheating linked in particular to sunshine or the use of transformers in confined areas.

Low levels of no-load and on-load losses require the use of the very best materials and technological know-how, which KOLEKTOR ETRA® possesses, enabling us to offer you the transformer that will cost you the least throughout its life cycle, whether on-load or off-load. The noise levels achieved by our transformers are low enough to considerably reduce the cost of building anti-noise devices.

For substation applications, we can offer transformers equipped with ONAN, ONAF, ODAF, OFAF, ODWF or OFWF cooling systems.

Finally, thanks to our EDF-ISATION program launched in 2016 with the SANERGRID® Group and our power transformer experts SYNERDIS®, you benefit from service and technical support in French, from the sales department to the design office, including factory project management, and site project management in France through our subsidiary SONEC® (see Accessories and Options tab).

Accessories and options

Thanks to our entity SONEC®, for your substation projects we can offer you essential services such as:

- Measure and 3D scan your transformer box for a customized design to suit your constraints.

- Reconnaissance and “last mile” marking.

- Transformer unloading and staging, by self-driving truck, turtle, rigging or craning.

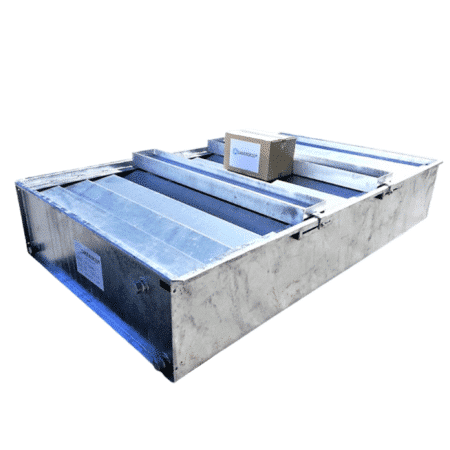

- Creation of a temporary storage area in flexible berm TRFLEX-ECO or TRFLEX-REFOR, or in watertight concrete with drainage skid PETRO PIPE.

- Replacement of the remote conservatory and installation of a safe maintenance platform with crutch ladder.

- Removal of contaminated pebbles from the old transformer pit, cleaning, pit lining, installation of fire suffocating covers for EXTICOV-CCF or EXTICOV-LHD transformers and installation of SPI rainwater drainage system at the bottom of the retention pit.

- Room-temperature galvannealing of your metal structures and high and medium-voltage gantries with our unique galvanic coating

- Protect your low and medium voltage systems from animal and plant intrusion with MIDSUN AVIFAUNE plastic-free, heat-free, glue-free protective covers.

- Installation of SANERVIB SP high-performance anti-vibration system.

Technical data

Additional information

| Scope of application | Electricity substations |

|---|

Additional information

Generic design data, which may vary according to the needs of each design:

Three grades of magnetic laminations are used:

- Conventional oriented C.G.O. class laminations.

- HI-B high magnetic orientation steel sheets.

- Laser-treated magnetic laminations.

The magnetic core, with 2, 3 or 5 legs, is stacked by overlapping individual steel sheets. Core laminations are securely held in place by heat-shrink polyglass strips and anti-magnetic steel clamps. The lower yoke and limbs are varnish glued. Oscillations and vibrations caused by magnetostriction forces are thus reduced to a minimum.

The frame formed by the clamp and the legs is fixed around the magnetic core, enabling the transformer to be transported safely and with adequate resistance to electromagnetic short-circuit forces.

The windings are made of high-purity electrolytic copper, Cu-ETP. Single- or multi-layer windings are used for phase currents up to 1000 A and rated voltages up to 72.5 kV. For higher voltage classes, disc windings are used: helical, continuous, or interlaced discs.

Specific electrical conductivity is 58 Sm/mm2.

The conventional yield strength (RP0,2) of conductors is 90 to 160 N/mm2.

Three thermal insulation classes are used:

- Enamel insulation (PVA), thermal class E (120°C), IEC 60317-0-2 compliant.

- 5A2-1M3 paper insulation, thermal class A (105°C), in compliance with IEC 554-3-5.

- Thermally improved paper insulation 5B1-2M3, thermal class E (120°C), compliant with IEC 554-3-5.

The transformers are equipped with a cooling system that can effectively dissipate the heat generated during operation. The cooling system is designed and tested for continuous operation with a declared capacity within the specified temperature limits. If there are no overload requirements, the cooling system is designed in accordance with IEC 60076-7. It includes radiators, various types of oil coolers or heat exchangers.

They can be separated from the reservoir and divided into several batteries or coolers, enabling rapid installation, or dismantling of systems.

The cooling system can be separated from the reservoir and located in separate installations for better heat dissipation. In this case, the system is equipped with pumps for faster oil circulation. Only types OF and OD can be used.

Our archives contain over 4000 different models. Most of them are currently in use in our service activities, and represent a unique source of tradition, innovation, experience, and excellence.

Thanks to its team of highly experienced and trained staff, Kolektor ETRA can carry out all types of routine and special tests required by international industry standards, including IEC, EN and ANSI.

- IEC 60076: Recommendations on temperature rise, insulation levels and dielectric tests, short-circuit withstand and an application guide.

- IEC 60354: Loading guide for oil-immersed power transformers.

- NF C13-200: Rules relating to the design and implementation of electrical installations with nominal voltages greater than 1 kV and less than or equal to 245 kV in alternating current and 50 Hz and 60 Hz preferred frequencies.

Each core, winding, reservoir, and other parts undergo mechanical and electrical inspection prior to assembly. The following operations are performed during the assembly procedure:

- Voltage ratio interphase measurement.

- Insulation resistance measurement.

- Measurement of short-circuit loss before drying process.

- Drying process and transformer oil monitoring.

Thanks to our SONEC® service business, we are qualified and able to support you in your projects for repair work, rebuilds and various overhauls of transformers, their components and equipment.

Contact us with your site information and project requirements.

You may also like…

-

ETRA HYDRO Oil-filled power transformer

0,00 € -

TRFLEX® -REFOR Flexible storage berm with reinforced tubular structure

0,00 € -

ETRA EOLIAN OFFSHORE Oil-filled power transformer

0,00 € -

TRFLEX® ECO Flexible storage berm for moderate mechanical constraints

0,00 € -

PETRO-PIPE PI-616-M2 Hydrocarbons filter for medium retention drainage

0,00 €